Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

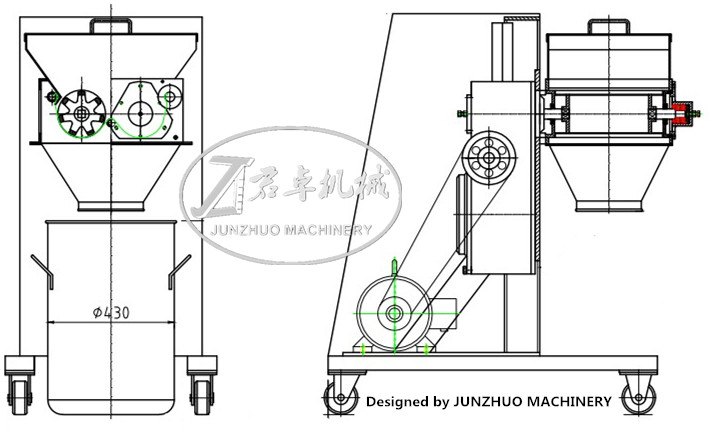

As we known, oscillating granulator is widely used in pharma, chemical and food industry. It is used for crushing dry blocks into small particles and make wet powder into granules.

JUNZHUO MACHINERY supply all kinds of oscillating granulators and their spare parts, such as screen sieves, gear rack and shaft, rotor and so on. We also provide customized design, explosion proof, dust collector, water cooling,no contaminated,316L ect.

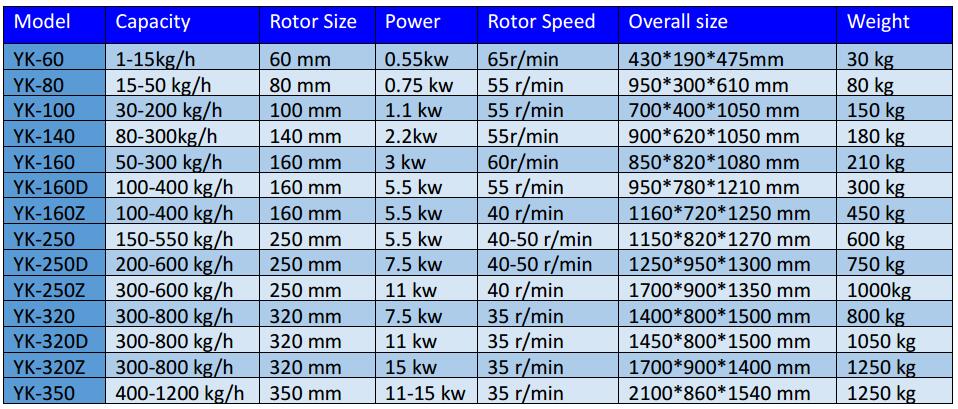

The technical data of single rotor oscillating granulator as follows.

It is including of lab model to large capacity, the smallest model is YK60, which is suitable for laboratory.

From the data we can see, the model is named by rotor diameter. The difference between standard model, D model and Z model is their application.

1.Standard modle is suitable for normal material.

2.We have improved the gear box and motor of YK160D,YK250D and YK320D model, so that they are available for various granule products and high density materials.

3.As for YK160Z,YK250Z and YK320Z model, they have larger power than YK series and YK-D series, so they are used for granulation of extractum materials.

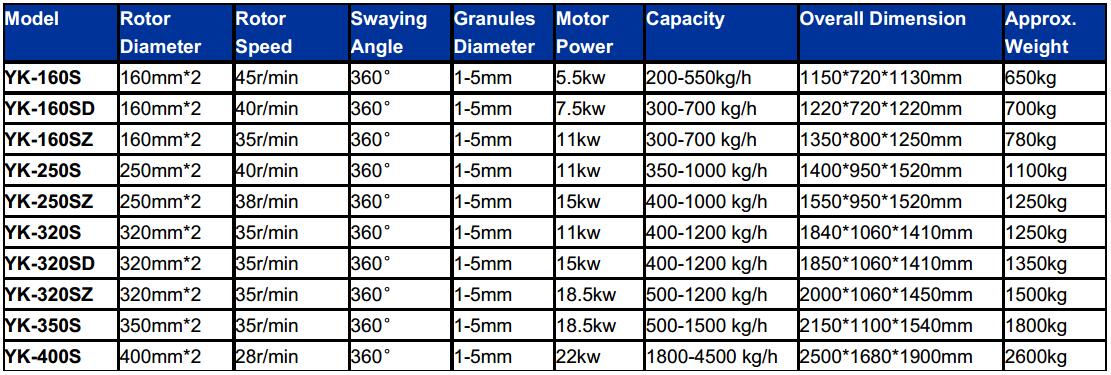

The technical data of YK double rotor oscillating granulator as follows. This series model is based on single rotor oscillating granulator. S means dual rotor, D means larger power, H means heavy duty. The application keeps the same as single rotor oscillating granulator.

So the most difference between single rotor and doule rotor oscillating granulator is the rotor number, motor power and machine size.

YK series single rotor oscillating granulator has lab model, but the smallest model of YK series doule rotor is YK160S, so it is not suitable for small capacity. The granule size is larger, the capacity is larger. The granule size is adjustable by changing the screen sieve size.

Before you choosing a right model, we need to know what is your raw material, what is the application, how about the granule size and capacity you required, other requirement. After confirming these information, it is easy to find which model is suitable for you.

If you have other question, please send email to jz@junzhuojx.com.

By continuing to use the site you agree to our privacy policy Terms and Conditions.