Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

Basket Granulator

The product is gently pressed to cylindrical granules, the granules will be more compact than YK series oscillating granulator.

In the product chamber of the basket granulator, two rotors operate in counter rotation. The upper rotor ensures good mixture and carries the material downwards. The lower extrusion rotor compresses the material and extrudes it through the screen sieve.

The basket granulator is often used in pellets with a porous structure and large surface area, easily dispersible granulate, such as drinks powder, sauces and soups, detergent, pesticides and so on.

JUNZHUO MACHINERY offers three kinds of basket granulators for your application. ZL series (ZL120, ZL-160, ZL200, ZL250, ZL-300, ZL-350, ZL-500, and ZL-550) basket extruder is the common type on the market, ZK series (ZK160, ZK200, ZK250, ZK300, ZK350, ZK500) basket extruder is improved of cutting knives to control granule length. XZK series (XZK300, XZK350, XZK500, XZK600) basket granulator is the unique design by our engineer, there is not only has cutting knives, the blade can be lifted up and down for better mixture.

This machine used for making wet powder into granules, such as chicken essence, sugar powder, herb powder,detergent powder and so on. The granule size depends on the screen sieve hole size, it ranges from 0.8mm to 8.0mm.

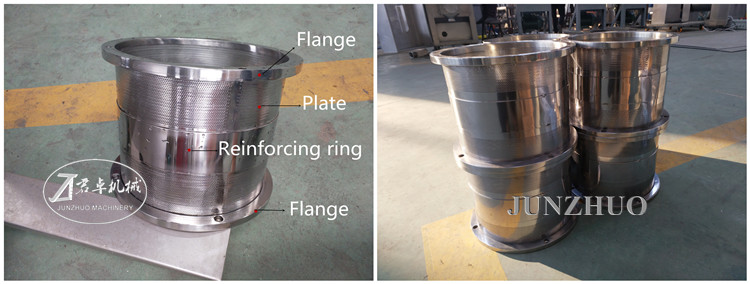

If you need smaller hole size, then it should be made as double layer screen sieve. As you known, the smaller of the hole size, then the thickness of plate will be thinner, it is easy to damage. The screen sieve made by SS304 or SS316L is avaiable.

Standard model

Double layer

If you want to know more information, please contact with us by email jz@junzhuojx.com

By continuing to use the site you agree to our privacy policy Terms and Conditions.