jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

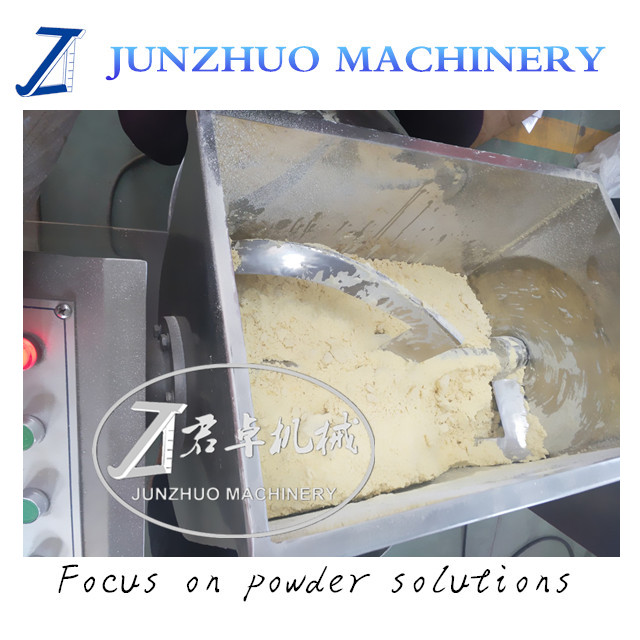

Z arm mixer is fitted with a heavy-duty Z-shaped blade. Counter rotating Z-blades apply high shear to the material. This type of mixers are rarely used for dry solids, but they are generally used for producing doughs and thick viscous pastes.

Z Arm / Sigma Mixer / Kneading Mixer

The action of the single/double z arm beaters will knead through every mix and thoroughly incorporating ingredients in a minimum of mixing time.Z arm mixer is fitted with a heavy-duty Z-shaped blade. Counter rotating Z-blades apply high shear to the material. This type of mixers are rarely used for dry solids, but they are generally used for producing doughs and thick viscous pastes.

After mixing, the wet powder can be used for making granules by JUNZHUO MACHINERY oscillating granulator, basket extruder or screw extruder. The mixing volume is depended on your required capacity. Z arm mixer can be made by Stainless steel 304 or 316 depend on the request of production and mirror polished of interior and exterior of the mixer, Operating panel and motor and all driving systems motor can be optioned ex-proof.

Features

· Capacities from 1 L up to 1000 L. (for Labs and R&D studies)

· Mixing duration 10 to 30 minutes with a good homogeneity.

· Bowl can be tilted to empty products.

· AISI 304 / 316 Stainless Steel and Carbon Steel as construction materials

· Suitable for heavy-duty applications

· Minimum cost

· Easy maintenance

| Model | Max Loading Volume | Operation Volume | Rotation Speed | Motor Power | Discharge Power | Discharge Angel | Overall Size | Approx. Weight |

| CH-1 | 1.3L | 1L | 24rpm | 0.2kw | by hand | 120 | 430*220*475mm | 30kg |

| CH-30 | 33L | 30L | 24rpm | 0.75kw | by hand | 360 | 1020*420*600mm | 120kg |

| CH-40 | 44L | 40L | 24rpm | 1kw | by hand | 360 | 1030*480*700mm | 150kg |

| CH-50 | 55L | 50L | 24rpm | 1.1kw | by hand | 360 | 1050*500*800mm | 200kg |

| CH-100 | 110L | 100L | 24rpm | 3kw | 0.55kw | 360 | 1400*500*1000mm | 350kg |

| CH-150 | 170L | 150L | 24rpm | 4kw | 0.75kw | 360 | 1600*600*995mm | 600kg |

| CH-200 | 220L | 200L | 24rpm | 5.5kw | 0.75kw | 360 | 1660*600*995mm | 620kg |

| CH-300 | 320L | 300L | 22rpm | 5.5kw | 1.1kw | 360 | 2200*680*1100mm | 800kg |

| CH-400 | 420L | 400L | 22rpm | 7.5kw | 1.5kw | 360 | 2400*710*1200mm | 850kg |

| CH-500 | 525L | 500L | 24rpm | 11kw | 2.2kw | 360 | 2400*850*1260mm | 920kg |

CH-1000 | 1050L | 1000L | 18rpm | 18.5-22kw | 3kw | 360 | 3150*1000*1500mm | 2100kg |

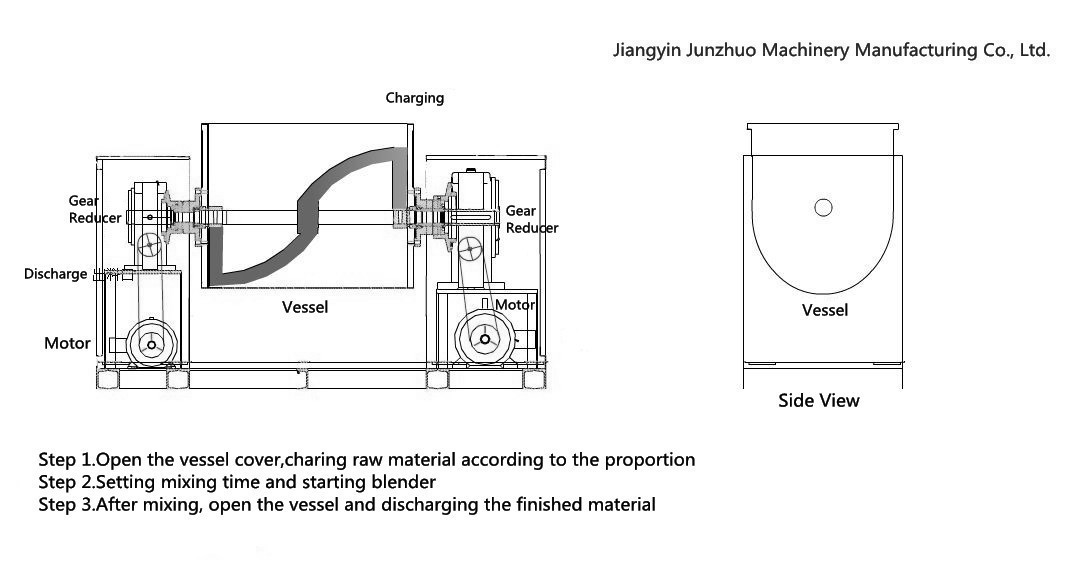

Working Principle

(1) Z arm type paddle is rotated, through mechanical driving, which pushes the material turn repeatedly and mix uniformly.

(2) Operate with electrical control, it can set mixing time to realize automatic stop and electric discharge upon expiration, thus improving the mix quality of each batch of material and realizing the high homogeneous mixing.

By continuing to use the site you agree to our privacy policy Terms and Conditions.