jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

GK80 model dry powder granulator, it is controlled by button.PLC control is available, it depends on your requirement. This roller compactor is easy to operate, dust collector, vibrating sifter and vacuum conveyor is optional.

In pharmaceutical, food and chemical industries, some raw material has the characteristic of low density (low specific gravity) and bad flow ability. By using the Roller Compactor – GK series dry granulator, it will improve the above characteristics and result in a bigger bulk density, higher specific gravity and good flow ability of granules.

This GK80 normal type roller compactor is a common machine with high performance. The roller and granulating systems are inner structure. With the advantage of simple structure and stable performance, it is widely used in the low cleanliness requirement industry, such as chemical, pesticide, rare earth and battery industries. It is also suitable for single material of pharmaceutical industry.

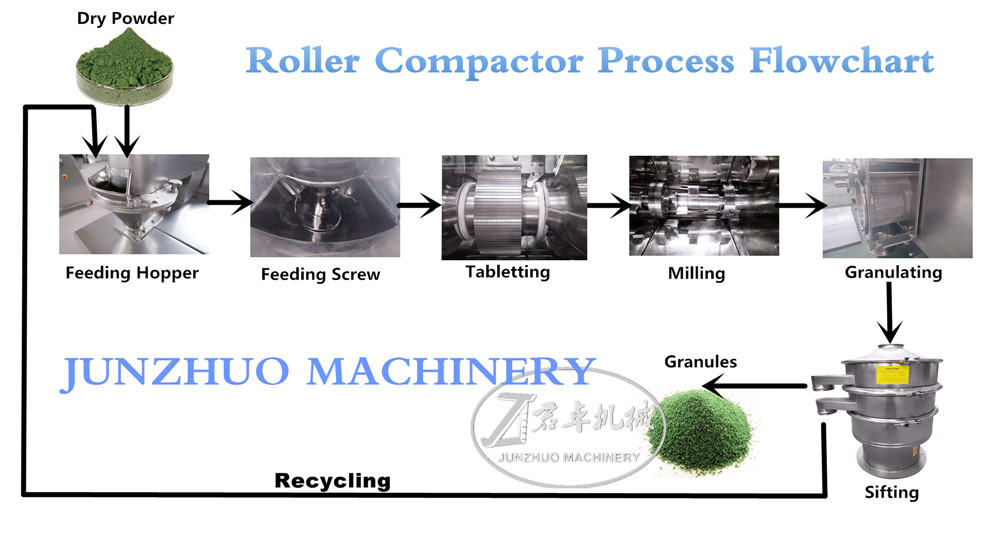

1. Material is fed between two counter-rotating roll presses.

2. The rolls apply extreme pressure, to press the material into a sheet-like form.

3. This sheet of material is then fed through a granulator, where it is broken up into uniformly sized granules.

4. Output is depended upon the mesh size and material density.

Normal type one is suitable for low cost, single or few materials need to change. (GK30 to GK500)

| Model | Output of sheet(kg/h) | Output of granule(kg/h) | Granules diameter (mm) | Total power (kw) | Feed Screw Speed (r/min) | Roll speed(r/min) | Overall size(mm) | Approx. weight (kg) |

| GK-30 | 3~10 | 0.5~2 | 0.5~3 | 2.5 | 6~33 | 4~25 | 880*550*1300 | 750 |

| GK-60 | 20~100 | 5~40 | 0.5~2.5 | 4.5 | 6~65 | 4~25 | 1085*650*1600 | 950 |

| GK-80 | 80~150 | 20~50 | 0.5~4 | 8.5 | 6~60 | 4~25 | 1600*1000*2300 | 1800 |

| GK-100 | 120~200 | 40~100 | 0.5~4 | 12.5 | 6~60 | 4~25 | 1800*900*2300 | 2000 |

| GK-120 | 150~250 | 75~100 | 0.5~4 | 12.5 | 6~60 | 4~25 | 1880*1020*2300 | 2300 |

| GK-150 | 200~350 | 100-150 | 0.5~4 | 18 | 5~50 | 4~25 | 2200*1050*2350 | 2800 |

| GK-200 | 250~500 | 120-300 | 1~5 | 24 | 5~50 | 5~22 | 2500*2150*2750 | 6500 |

| GK-250 | 300~700 | 200-300 | 1~10 | 27 | 5~45 | 5~22 | 2800*1800*2900 | 6800 |

| GK-300 | 400~1000 | 150-400 | 1~10 | 30~40 | 5~40 | 5~22 | 3000*2000*3000 | 7000 |

| GK-400 | 500~1200 | 300-800 | 1~10 | 42 | 5~40 | 5~20 | 3400*1800*3500 | 7200 |

| GK-500 | 600~1500 | 400-1200 | 1~10 | 42~45 | 5~40 | 5~20 | 3500*1800*3500 | 7800 |

1. No water or any organic solvents. Therefore, this method is especially attractive for drugs, which are moisture or heat sensitive.

2. Suitable for compounds that either have a low melting point or degrade rapidly during heating, as the method does not involve any drying step.

3. Forming porous tablets thus allowing water to penetrate more easily into the tablet. This leads to improved disintegration behavior of tablets.

4. Roll compaction technique provides an efficient and easily automated process, which is environmentally friendly.

5. Low operational cost.

6. Dust problems are minimized or avoided and the die filling during tableting is improved.

7. Roll compaction/dry granulation can be used, if the drug or the excipient is poorly flowing or sensitive to heat or moisture.

8. It can also be used for densification of powders prior to encapsulation.

9. Control particle hardness and provide granule integrity during conveying and processing steps.

10. Control dust and reduce environmental risk, waste and cross-contamination.

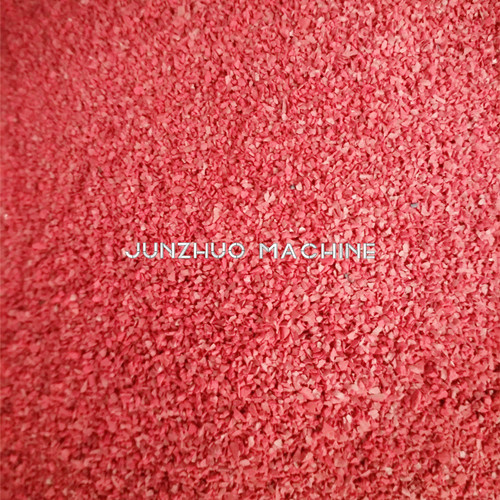

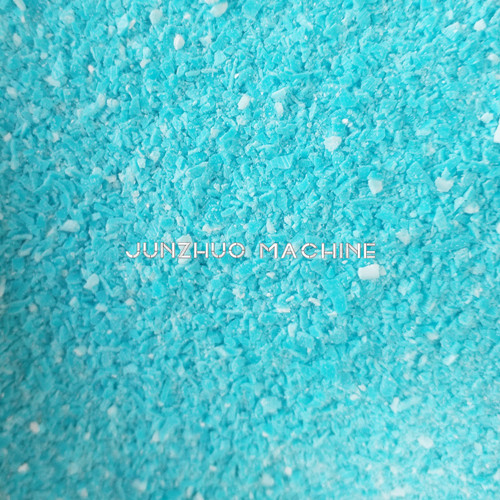

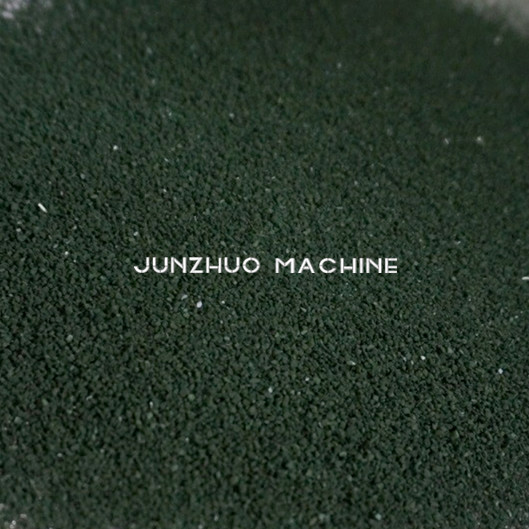

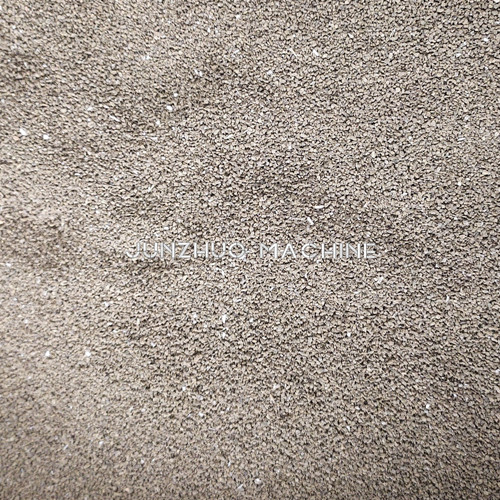

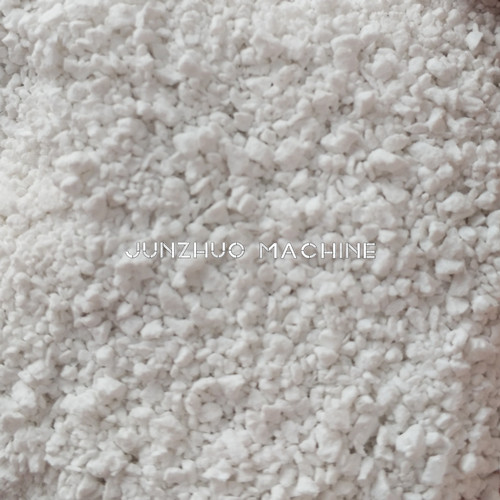

After granulation(Different materials in different application). It is ok for testing raw material if you can send sample to us.

Food Color |  Catalyst |  Chinese Herb |

Ginseng |

|  SiO2 |

By continuing to use the site you agree to our privacy policy Terms and Conditions.