jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

Conical Screen Milling, or simply 'Cone Milling', is widely recognized as one of the most efficient and beneficial methods for size reduction in the powder processing industries. Benefits of this method include a reduction in process times, cleaning, noise and dust levels, thus making this a highly desirable solution for size reduction of materials.

型号Model | 旋簧长度 (mm) Cone Knife Length | 滤孔直径 (mm) Screen Sieve Diameter | 生产能力(kg/h)Capacity | 电机功率 (KW) Motor Power

| 转速Rotation Speed | 外型尺寸 (mm)Overall Size | 重量(kg) Approx. Weight |

KZL160 | 120 | 1-8 | 150-450 | 1.5 | 变频调速200-1450或400-3000 Frequency 200-1450r/min or 400-3000r/min | 1000×720×1170 | 140 |

KZL180 | 135 | 1-8 | 150-550 | 1.5 | 1050×720×1200 | 160 | |

KZL200 | 140 | 1-8 | 200-700 | 1.5-2.2 | 1100×750×1300 | 190 | |

KZL250 | 180 | 1-8 | 400-1500 | 2.2-3 | 1350×800×1550 | 260 | |

KZL300 | 220 | 1-8 | 450-2500 | 5.5 | 1500×900×1700 | 400 |

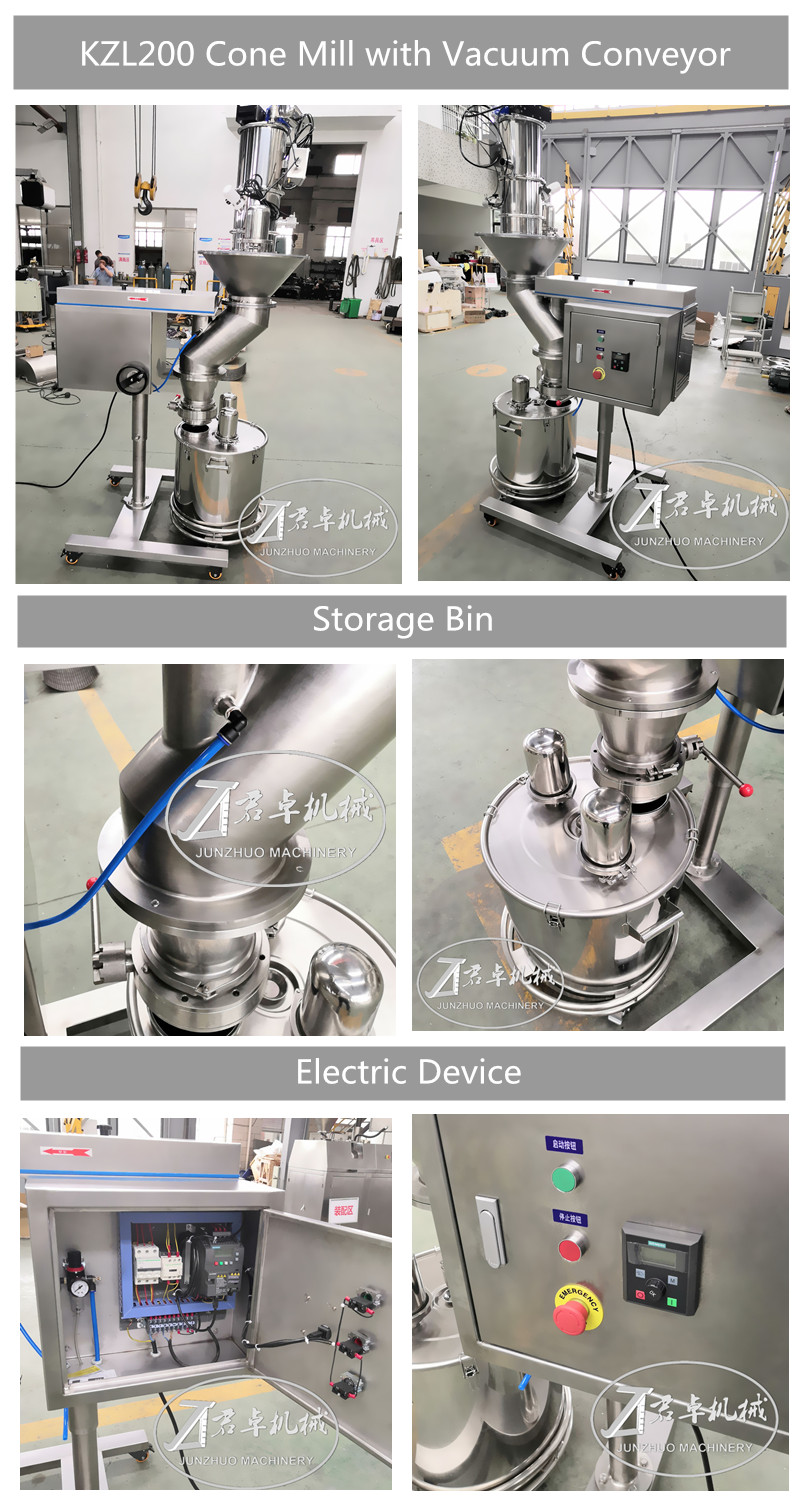

Cone Mill--Solid Particle Size Reduction Equipment

Cone milling is a gentle, low energy size reduction mill ideal for fatty, heat sensitive, sticky, moist or fragile products. It alleviates traditional milling problems of noise, dust and heat generation as ideal for use in food and pharmaceutical applications.

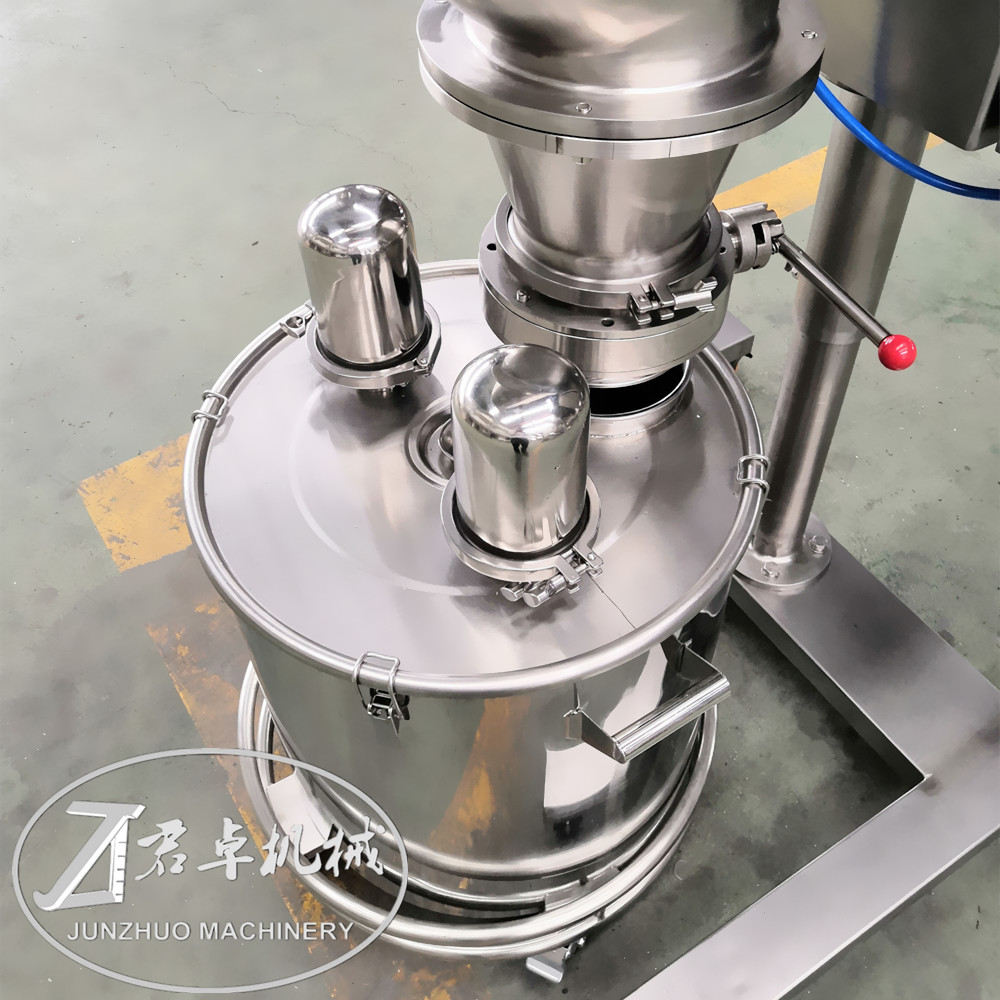

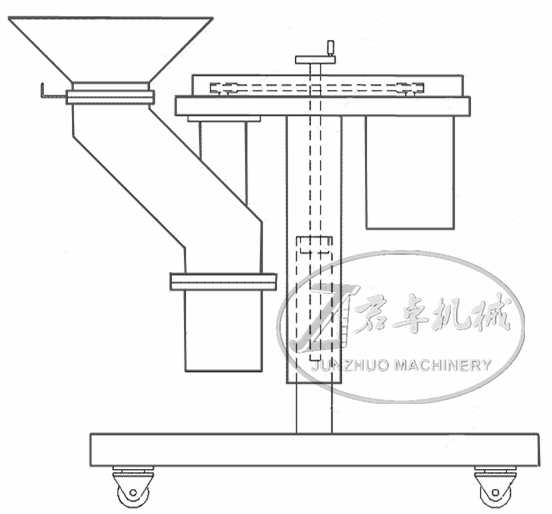

The conical mill operates by having the product being fed into the mill by gravity or vacuum. A rotating impeller forces the material outward to a conical screen surface, where it is sized and passed through the openings in the screen. Once finished, the product simply drops through the milling chamber to a receptacle underneath.

Conical mills come in a variety of sizes from tabletop lab models to full-size high-capacity machines for use in processing large quantities of material, and the impeller and screen can be customized for each individual use. The machines can be used not only to reduce the size of particles, but also for deagglomeration, sieving, dispersion, and mixing.

Application:

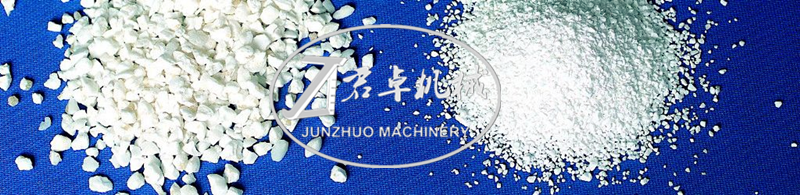

1. Raw Material Grinding & De-agglomeration: It has the function of grinding the lumps to smaller particle size. This can pre-process raw material to eliminate irregularities, therefore it will improve the mixing efficiency.

2. Size Reduction: Fix the oversize raw material to a smaller and uniform particle size.

3. Dry Granulation & Milling: Dry granulation can reduce granule/powder into desired range of particle size.

4. Wet Granulation & Milling: Wet material is reduced to a small and uniform particle size before drying. It produces small and uniform size fine powder form agglomerates that are produced by mixer. This is perfect for the dryer to take short time of achieving the uniform drying.

Pipeline Type(Buttom-driven)

| Model | KZL-160 | KZL-160(clean type) | KZL-180 | KZL-200 | KZL-250 |

| Capacity | 150-300kg/h | 150-300kg/h | 150-400kg/h | 200-500kg/h | 300-1000kg/h |

| Spring Length | 120mm | 120mm | 135mm | 140mm | 180mm |

| Screen Sieve Size | 1-8mm | 1-8mm | 1-8mm | 1-8mm | 1-8mm |

| Motor Power | 1.5kw | 3kw | 1.5kw | 1.5-2.2kw | 2.2-3kw |

| Rotation Speed | 200-1450 r/min or 400-3000r/min | ||||

| Overall Dimension | 1000*720*1170mm | 1150*600*1290mm | 1050*720*1200mm | 1100*750*1300mm | 1350*800*1550mm |

| Approx. Weight | 140kg | 340kg | 160kg | 190kg | 260kg |

The material to be processed enters into the feed inlet of the cone mill, which drops into the conical sieve chamber. The rotary knife rotates against the material, and grinds the granules against the sieve mesh surface. The granules are ground into particles by the shearing action produced by the rotary knife and sieve mesh, and then discharged through the sieve holes. This model is buttom driven.

By continuing to use the site you agree to our privacy policy Terms and Conditions.