jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

WFJ series air classifying mill pulverizer has been widely used for milling/pulverizing high fiber content materials, heat sensitive materials and brittle materials in food, chemical and pharmaceutical industry.

Main application:

Super-micro mill is mainly used to produce fine powder and super fine powder.This high performance equipment consists of main frame, feeding device, crushing device, discharge pipe, transmission and motor, supporting by the host, dust collector, high pressure centrifugal fan, rotary valve, whirlpool aggregator and electric control cabinet, etc. The particle size can be adjusted during operation and the fineness can be reached at 80-320 mesh. The equipment has a self-cooling function.It is widely used for material grinding in pharmaceutical, chemical, foodstuff, etc.

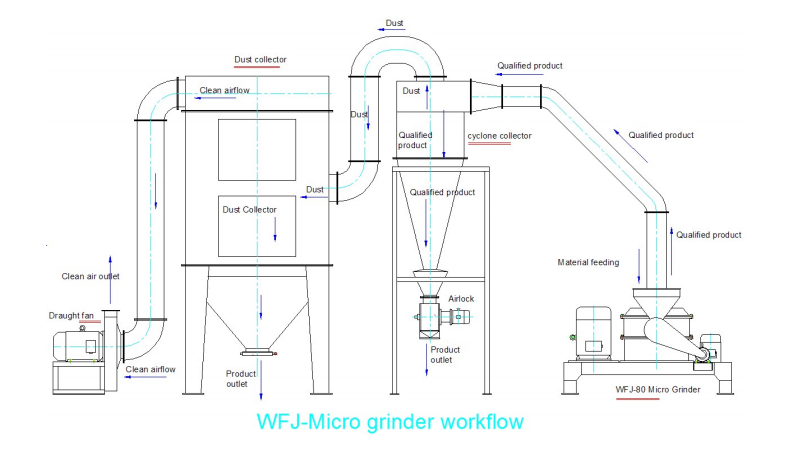

Working priciple:

Raw material is delivered to the grinding chamber by a screw conveyor, cut and sheared by the high speed rotating blades. Then the material is moved into the cyclone separator by means of negative pressure. No dust during operation makes it cleaner.

Main Features

1. Alloy steel hammer blades and rotor

2. GMP and food grade design

3. Negative working condition can prevent dust and be suitable for heat sensitive material pulverization.

4. Output size is adjustable via air classifier and air flow rate.

5. Feeding rate is automatic controlled

6. Particle size distribution can be accurately controlled

| Model | WFJ-350 | WFJ-450 | WFJ-500 | WFJ-750 |

| Capacity | 20-200 kg/h | 40-500 kg/h | 60-800 kg/h | 120-1800 kg/h |

| Material Size | <15mm | <15mm | <15mm | <15mm |

| Powder Size | 80-320 mesh | 80-320 mesh | 80-320 mesh | 80-320 mesh |

| Main Motor | 7.5 kw | 15 kw | 22 kw | 45 kw |

| Grading Motor | 1.1 kw | 2.2 kw | 7.5 kw | 11 kw |

| Draught Fan | 5.5 kw | 7.5 kw | 18.5 kw | 37 kw |

| Feeding Motor | 0.37 kw | 0.75 kw | 0.75 kw | 1.1 kw |

| Discharge Motor | 0.75 kw | 0.75 kw | 0.75 kw | 1.1 kw |

| Cruhsing Speed | 6500 rpm | 5600 rpm | 4400 rpm | 3100 rpm |

| Grading Speed | 4000 rpm | 4000 rpm | 3500 rpm | 3000 rpm |

| Overall Size | 5×1.4×2.8 m | 5.4×1.5×2.9 m | 6.6×2×3.6 m | 9.8×2.7×4.9m |

| Weight | 1600 kg | 1800 kg | 2300 kg | 3100 kg |

1. Grinding chamber

Alloy steel hammer heads and specially heat-treated teeth liner can considerablly increase life-span.

Inside |

Outside |

2. Screw feeder

Invert is equipped to accurately control the feeding rate, which is the precondition for stable and reliable operation.

|  |

3.Product collecting system

Product collecting system consists of cyclone, bag house and draft fan to prevent dust and increase collection rate.

|  |

4. Control box

It is very easy to control the whole unit and get the fine powder as your requirement.

|  |

By continuing to use the site you agree to our privacy policy Terms and Conditions.