jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

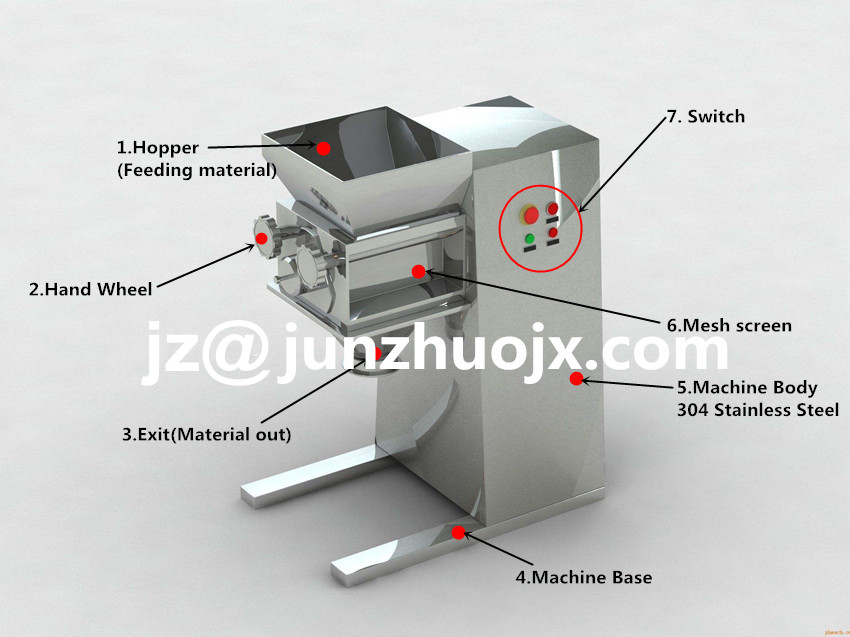

This model is a unique design for Explosive Material, the rotor is specially for explosive powder. There is a support which can put on a tray, so that it is easy to get the output product.

This is a very popular granulating machine used for forming the required particle sizes from wet powder material, or crushing dried blocks into granules as you need. Our YK140 oscillating granulators are widely used in pharmaceutical, food, chemical, cosmetic and nutrition industries. This machine is a customized design with special rotor, which is suitable explosive material.

YK 140 oscillating granulator has 2.2kw motor, with the capacity of 80 to 300kg/h, the output capacity depends on material characteristic and screen mesh sieve. Oscillation speed is 55 rpm, it can be controlled by inverter. Motor is controlled by push button station, driven by reduction gear box. Open hopper, continuous adding raw materials, a detachable cover is available. It has 4 moveable wheels has bracket assembly, easy to clean, maintain and operate.

JUNZHUO MACHINERY offers customized design, such as hermetic seal , explosion proof motor, dust collector and so on. Please do not hesitate to send the URS to us, we will help you to find the unique one to meet your requirement.

Salient Features:

Design is cGMP – Current Good Manufacturing Practices compliance.

All Product contact parts AISI 316 & non-contact parts AISI 304.

Uniformly granulation & fewer fines of wet material and dry materials.

Easy to operate, move, clean, maintain

An Inline granulation & user friendly.

Dust-free crushing

Model size from YK60 to YK350, YK-60 oscillating granulator is the smallest model, which can be used for lab testing.

| Model | Capacity | Rotor Size | Power | Rotor Speed | Overall size | Weight |

| YK-60 | 1-15kg/h | 60 mm | 0.55kw | 65r/min | 430*190*475mm | 30 kg |

YK-60 New (new) | 1-15kg/h | 60 mm | 0.55kw | 65r/min | 520*300*875mm | 60kg |

| YK-80 | 15-50 kg/h | 80 mm | 0.75 kw | 55 r/min | 950*300*610mm | 80 kg |

| YK-100 | 30-200 kg/h | 120 mm | 1.1 kw | 55 r/min | 700*400*1050mm | 150 kg |

| YK-140 | 80-300kg/h | 140 mm | 2.2kw | 55r/min | 900*620*1050mm | 180 kg |

| YK-160 | 50-300 kg/h | 160 mm | 3 kw | 60r/min | 850*820*1080mm | 210 kg |

| YK-160D | 100-400 kg/h | 160 mm | 5.5 kw | 55r/min | 950*780*1210mm | 300 kg |

| YK-160Z | 100-400 kg/h | 160 mm | 5.5 kw | 40 r/min | 1160*720*1250mm | 450 kg |

| YK-250 | 150-550 kg/h | 250 mm | 5.5 kw | 40-50 r/min | 1150*820*1270mm | 600 kg |

| YK-250D | 200-600 kg/h | 250 mm | 7.5 kw | 40-50 r/min | 1250*950*1300mm | 750 kg |

| YK-250Z | 300-600 kg/h | 250 mm | 11 kw | 40 r/min | 1700*900*1350mm | 1000kg |

| YK-320 | 300-800 kg/h | 320 mm | 7.5 kw | 35 r/min | 1400*800*1500mm | 800 kg |

| YK-320D | 300-800 kg/h | 320 mm | 11 kw | 35 r/min | 1450*800*1500mm | 1050 kg |

| YK-320Z | 300-800 kg/h | 320 mm | 15 kw | 35 r/min | 1700*900*1400mm | 1250 kg |

| YK-350 | 400-1200 kg/h | 350 mm | 11-15 kw | 35 r/min | 2100*860*1540mm | 1250 kg |

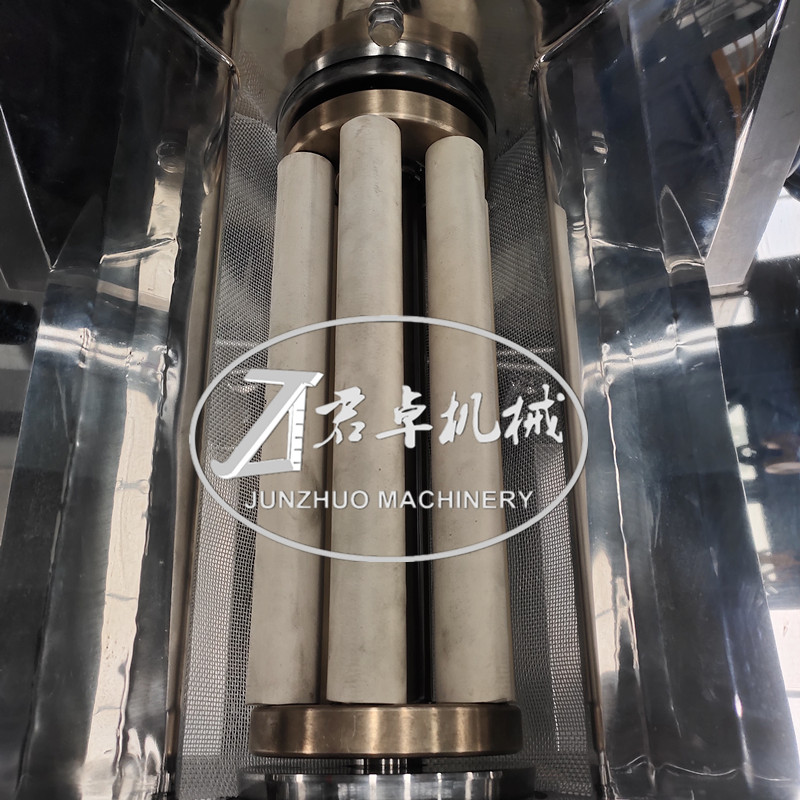

The principle of an oscillating granulator is to mechanically pass compacted material through a wire mesh screen or plate using an oscillating rotoThe principle of an oscillating granulator is to mechanically pass compacted material through a wire mesh screen or plate using an oscillating rotor. The rotor speed and rotation time are variable in the clockwise or counterclockwise directions. Particle size is controlled through mill-screen size, rotor speed, and the rotor's rotation angle.

JUNZHUO MACHINERY offerrs all the spare parts, such as the rotor,screen sieve and hand wells. Screen sieves can be made by perforated plate or mesh sieve or nylon, it just depends on your requirement.

Screen Sieves

Nylon Sieve |  Wire Mesh |  Perforated Plate |

By continuing to use the site you agree to our privacy policy Terms and Conditions.