jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

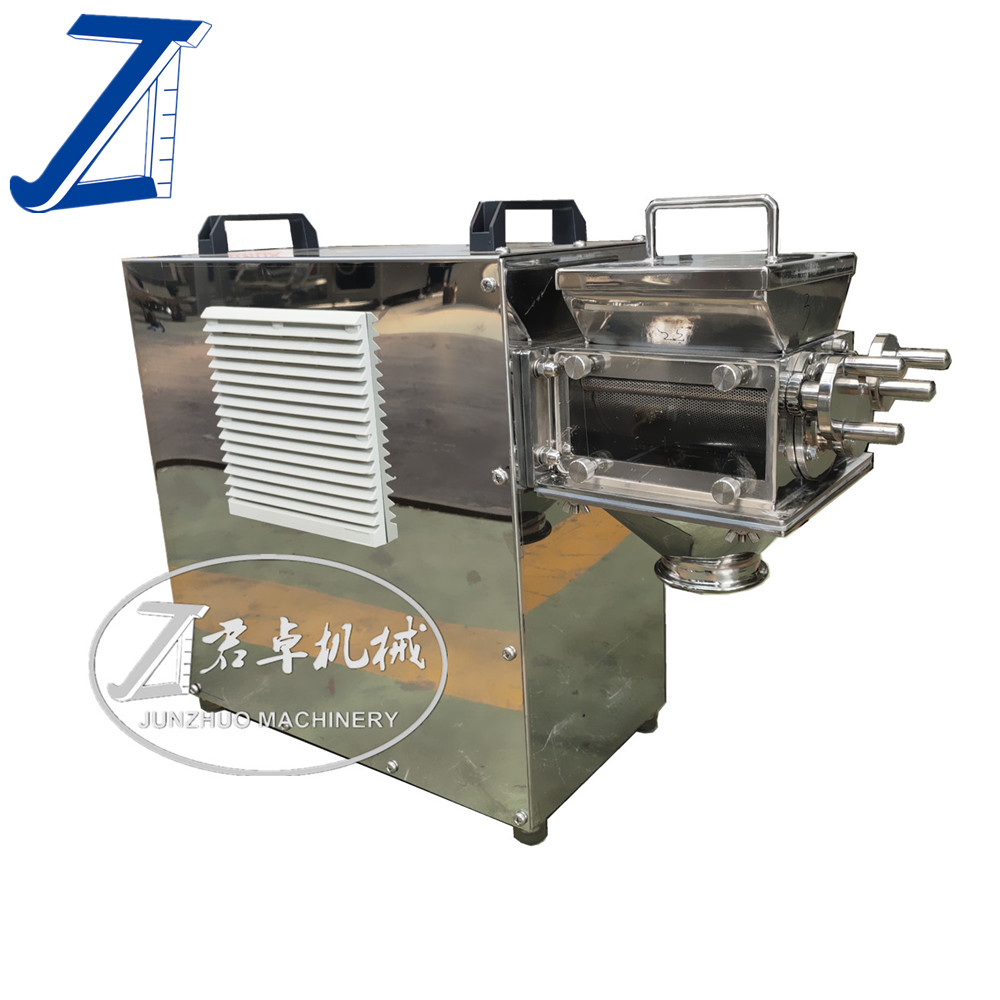

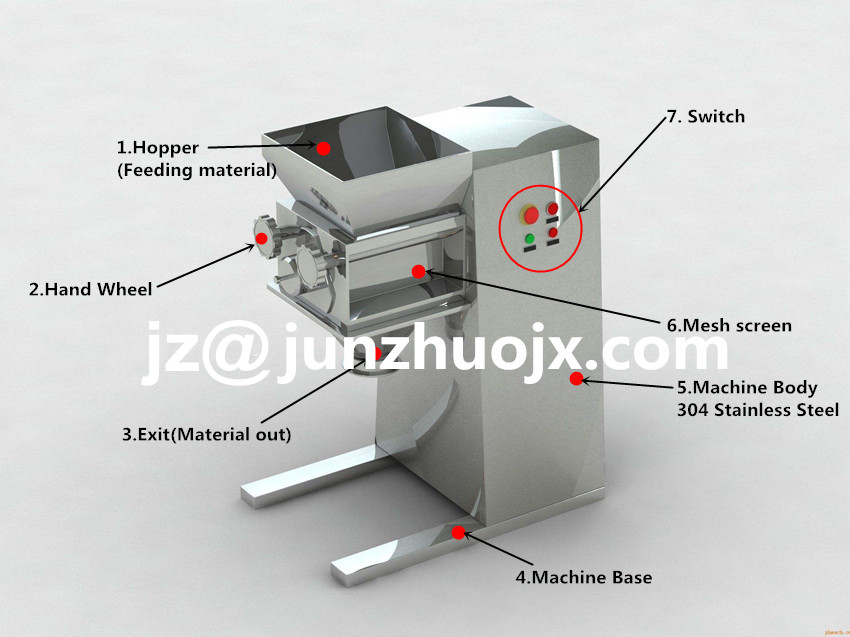

Oscillating Granulator is used for both wet and dry granulation process. Oscillating Granulators make quality of granules better. The unique oscillatory rotor action ensures high output and efficient granulation. Oscillating Granulators are available in Standard & GMP models with SS 304 / SS 316L Contact Parts. Explosion proof motor is optional in some special application.

General Description

Oscillating Granulator is used for both wet and dry granulation process. Oscillating Granulators make quality of granules better. The unique oscillatory rotor action ensures high output and efficient granulation. Oscillating Granulators are available in Standard & GMP models with SS 304 / SS 316L Contact Parts. Explosion proof motor is optional in some special application.

YK 60 sway lab granulator has 0.55kw motor, with the capacity of 1 to 15 kg/h, it is designed for lab research and test. Oscillation speed is 65 rpm, it can be controlled by Variable-frequency drive. Motor is controlled by push button station, driven by reduction gear box. Open hopper, continuous adding wet or dry material, a cover is available. 4 moveable wheels has bracket assembly ensure the maintenance free.

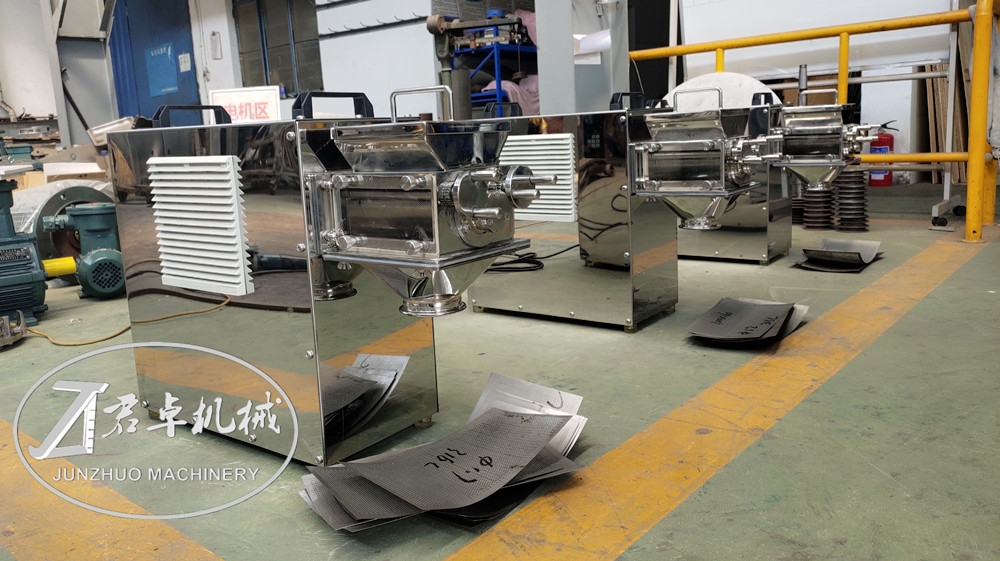

YK60 series lab granulators include of standard model and updated model, the main difference is the overall size and total weight. Due to Explosion-proof motor and inverter only can be installed on the updated type granulator, so the machine frame is bigger than standard model.

Salient Features:

No hidden edges and dead points

Design to operate at maximum granule size

Minimum dust exposure

Emergency stop switch

Motor overload protection

Wheels with lock for easy movement during washing

Technical Data

Capacity:5-15 kg/h

Speed:20-65rpm

Motor power:550W

Rotor diameter:60mm

Swing angel:360°

Overall size:730*240*520mm

Approx. weight:50kg

This machine has equipped with inverter to control the rotation speed, the screen sieves can be perforated plate, wire mesh sieve or nylon sieve. Material of SS304 or SS316L is avaiable.

Model size from YK60 to YK350, YK-60 oscillating granulator is the smallest model, which can be used for lab testing.

| Model | Capacity | Rotor Size | Power | Rotor Speed | Overall size | Weight |

| YK-60 | 1-15kg/h | 60 mm | 0.55kw | 65r/min | 430*190*475mm | 30 kg |

YK-60 New (new) | 1-15kg/h | 60 mm | 0.55kw | 65r/min | 520*300*875mm | 60kg |

| YK-80 | 15-50 kg/h | 80 mm | 0.75 kw | 55 r/min | 950*300*610mm | 80 kg |

| YK-100 | 30-200 kg/h | 120 mm | 1.1 kw | 55 r/min | 700*400*1050mm | 150 kg |

| YK-140 | 80-300kg/h | 140 mm | 2.2kw | 55r/min | 900*620*1050mm | 180 kg |

| YK-160 | 50-300 kg/h | 160 mm | 3 kw | 60r/min | 850*820*1080mm | 210 kg |

| YK-160D | 100-400 kg/h | 160 mm | 5.5 kw | 55r/min | 950*780*1210mm | 300 kg |

| YK-160Z | 100-400 kg/h | 160 mm | 5.5 kw | 40 r/min | 1160*720*1250mm | 450 kg |

| YK-250 | 150-550 kg/h | 250 mm | 5.5 kw | 40-50 r/min | 1150*820*1270mm | 600 kg |

| YK-250D | 200-600 kg/h | 250 mm | 7.5 kw | 40-50 r/min | 1250*950*1300mm | 750 kg |

| YK-250Z | 300-600 kg/h | 250 mm | 11 kw | 40 r/min | 1700*900*1350mm | 1000kg |

| YK-320 | 300-800 kg/h | 320 mm | 7.5 kw | 35 r/min | 1400*800*1500mm | 800 kg |

| YK-320D | 300-800 kg/h | 320 mm | 11 kw | 35 r/min | 1450*800*1500mm | 1050 kg |

| YK-320Z | 300-800 kg/h | 320 mm | 15 kw | 35 r/min | 1700*900*1400mm | 1250 kg |

| YK-350 | 400-1200 kg/h | 350 mm | 11-15 kw | 35 r/min | 2100*860*1540mm | 1250 kg |

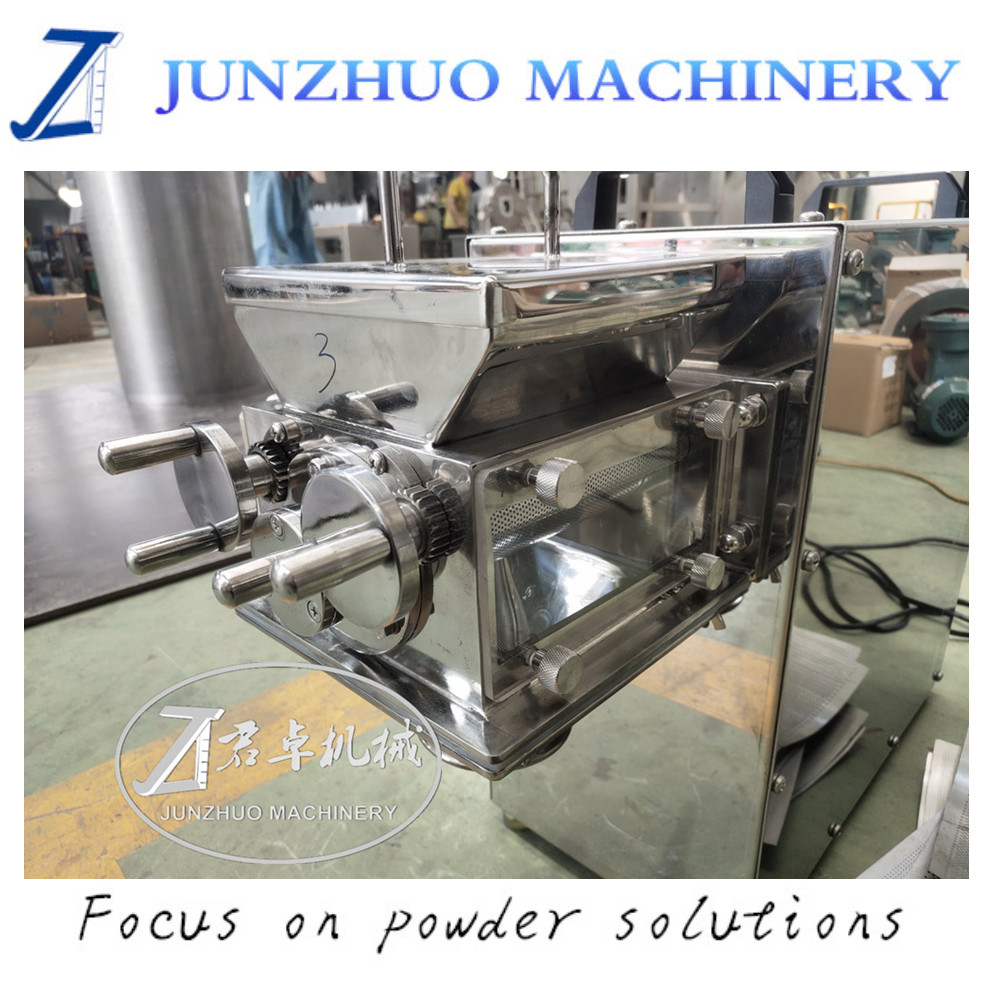

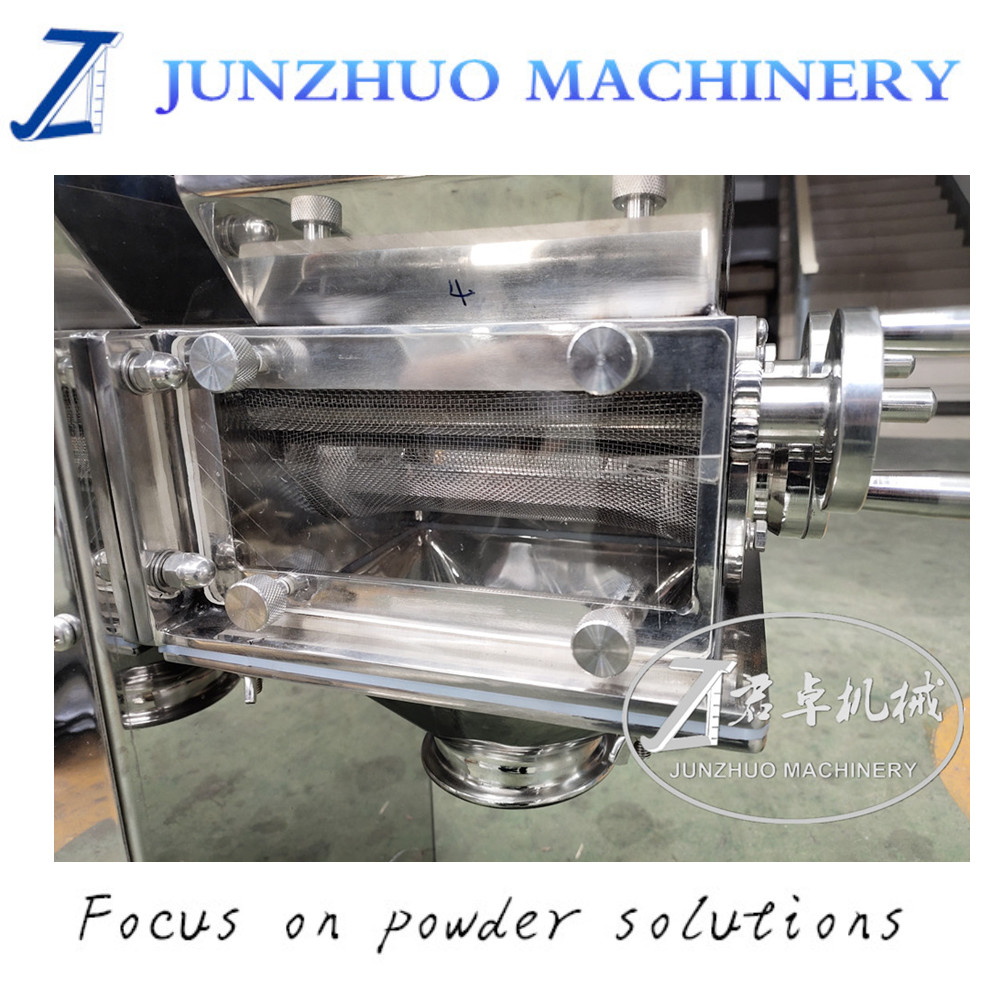

Oscillating Granulator has one rotor horizontal axis at about 360 degree. There is one half round sieve mounted at the bottom of the rotor. Product is charged from the top through in feeding hopper and material falls on the rotor. The particles are broken by a set of oscillating bars arranged in cylindrical form over a screen of suitable mesh. Due to the sharp edges on rotor, the downsizing of particle takes place and through sieve material gets pushed outward from the bottom opening. The granules can be produced in varying sizes depending on the employed sieve mesh.

JUNZHUO MACHINERY offerrs all the spare parts, such as the rotor,screen sieve and hand wells. Screen sieves can be made by perforated plate or mesh sieve or nylon, it just depends on your requirement.

Screen Sieves

Nylon Sieve |  Wire Mesh |  Perforated Plate |

Others

Hand Wheels |  Single Rotor |

By continuing to use the site you agree to our privacy policy Terms and Conditions.