jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

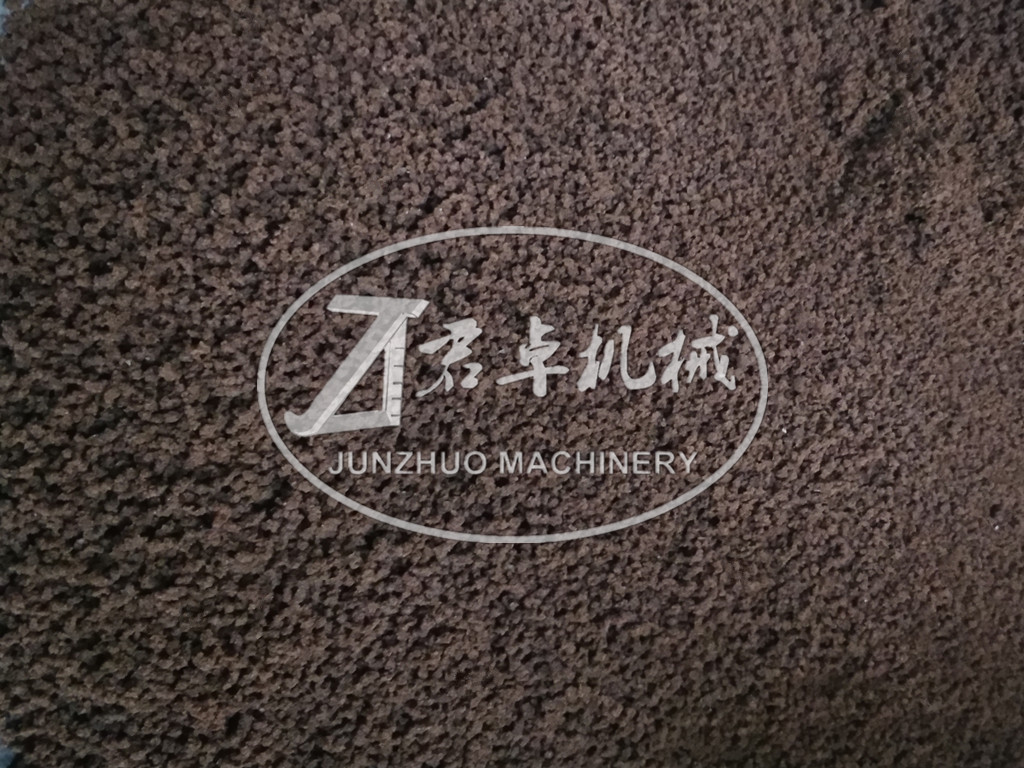

The basket granulator is often used in pellets with a porous structure and large surface area, easily dispersible granulate, such as drinks powder, sauces and soups, detergent, pesticides and so on.

The product is gently pressed to cylindrical granules, the granules will be more compact than YK series oscillating granulator.

In the product chamber of the basket granulator, two rotors operate in counter rotation. The upper rotor ensures good mixture and carries the material downwards. The lower extrusion rotor compresses the material and extrudes it through the screen sieve.

The basket granulator is often used in pellets with a porous structure and large surface area, easily dispersible granulate, such as drinks powder, sauces and soups, detergent, pesticides and so on.

JUNZHUO MACHINERY offers three kinds of basket granulators for your application. ZL series (ZL120, ZL-160, ZL200, ZL250, ZL-300, ZL-350, ZL-500, and ZL-550) basket extruder is the common type on the market, ZK series (ZK160, ZK200, ZK250, ZK300, ZK350, ZK500) basket extruder is improved of cutting knives to control granule length. XZK series (XZK300, XZK350, XZK500, XZK600) basket granulator is the unique design by our engineer, there is not only has cutting knives, the blade can be lifted up and down for better mixture.

All the above models are on the CE certificate.

| Model | Capacity | Impeller Diameter | Hole Size | Motor Power | Rotary Speed | Overall size | Weight |

| ZL-120 | 5-20 kg/h | 118 mm | 0.8-2mm | 1.5 kw | 55 r/min | 680*380*680mm | 100kg |

| ZL-200 | 100-150 kg/h | 198 mm | 1-2.2mm | 3kw | 50 r/min | 1100*550*1050mm | 300kg |

| ZL-250 | 140-200 kg/h | 248 mm | 1.2-2.2mm | 4-5.5kw | 50 r/min | 1120*550*1200mm | 350kg |

| ZL-300 | 140-400 kg/h | 268 mm | 1.2-3mm | 5.5-7kw | 45r/min | 1120*550*1200mm | 400kg |

| ZL-350 | 150-600 kg/h | 348 mm | 1.2-5mm | 7.5-11kw | 40r/min | 1500*750*1350mm | 500kg |

| ZL-500 | 150-850 kg/h | 498 mm | 1.2-8mm | 18.5 kw | 35r/min | 1900*850*1580mm | 1600kg |

| ZL-550 | 200-1000 kg/h | 548 mm | 1.2-8mm | 22 kw | 35r/min | 2000*900*1580mm | 1800kg |

Features

Extrudates well suited for Spheronization

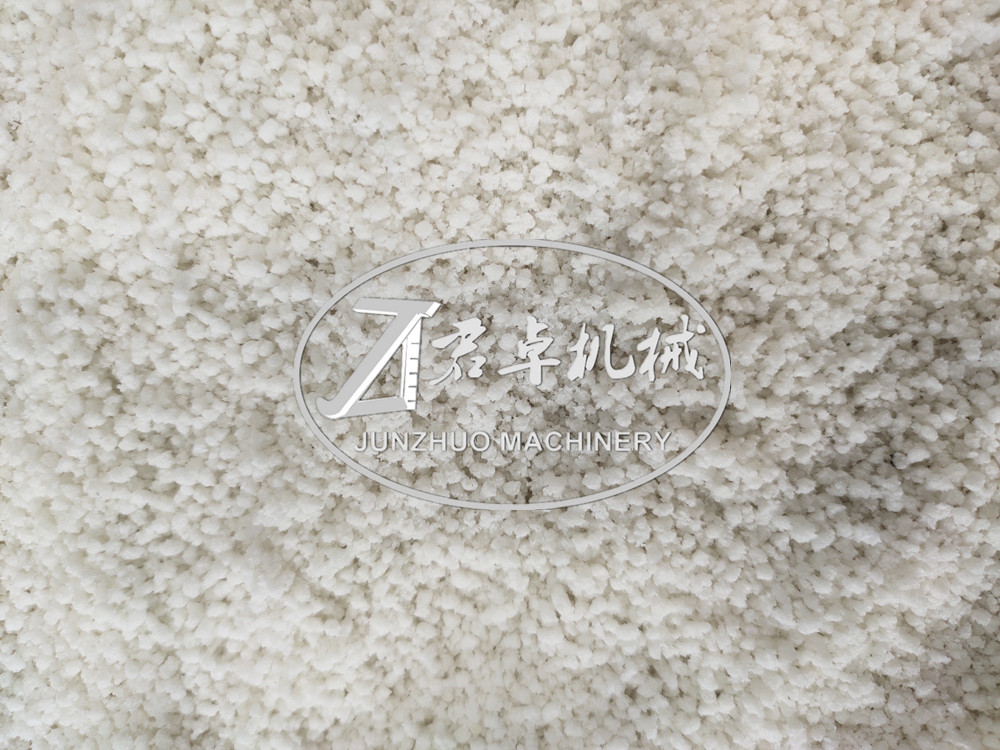

Continuous granulation into φ 0.8~8mm columnar granules

Improvement of handling and dosing properties

Low densification

Low dust cylindrical pellets with large surface

Good deformation properties

Better particle size distribution

Improved flow ability

Easy disassembly for cleaning

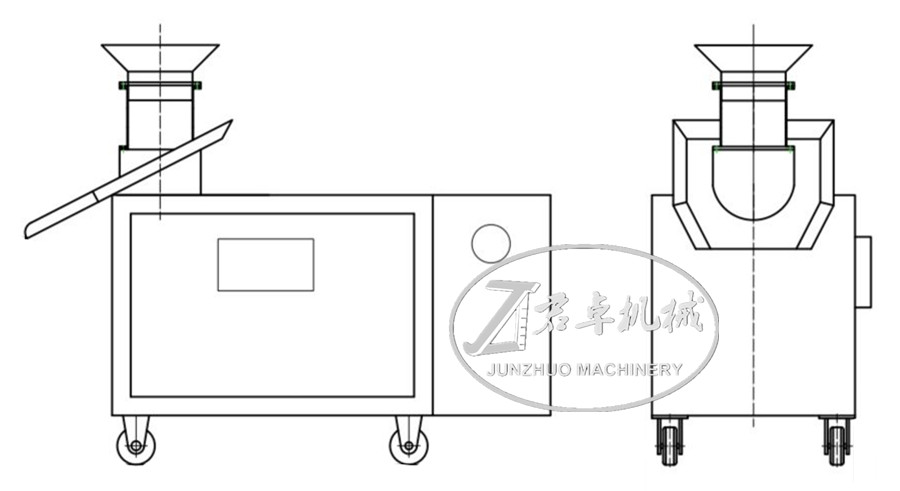

Wet mixed powder (raw material) is added into the feeding hopper. In the upper chamber of our basket extruders the counter rotating internal breaker bar system breaks larger clumps of wet powder to allow gravity to convey the wetted mass down into the bottom extrusion rotor arms which, in turn, densifies the material and extrudes it through the screen sieve. Formed materials are discharged without damage by our proprietary discharge chute design. After drying, finished product will be obtained.

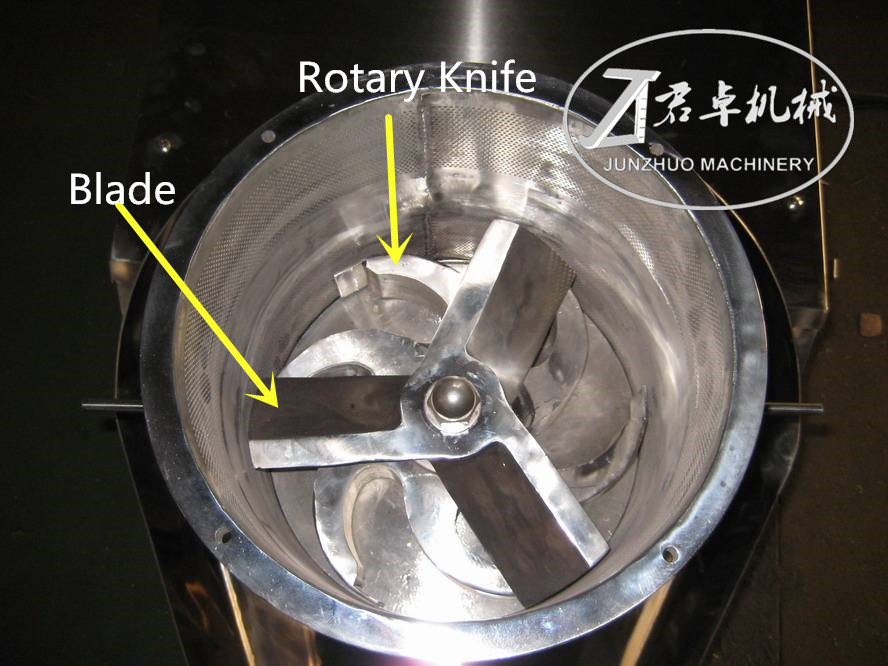

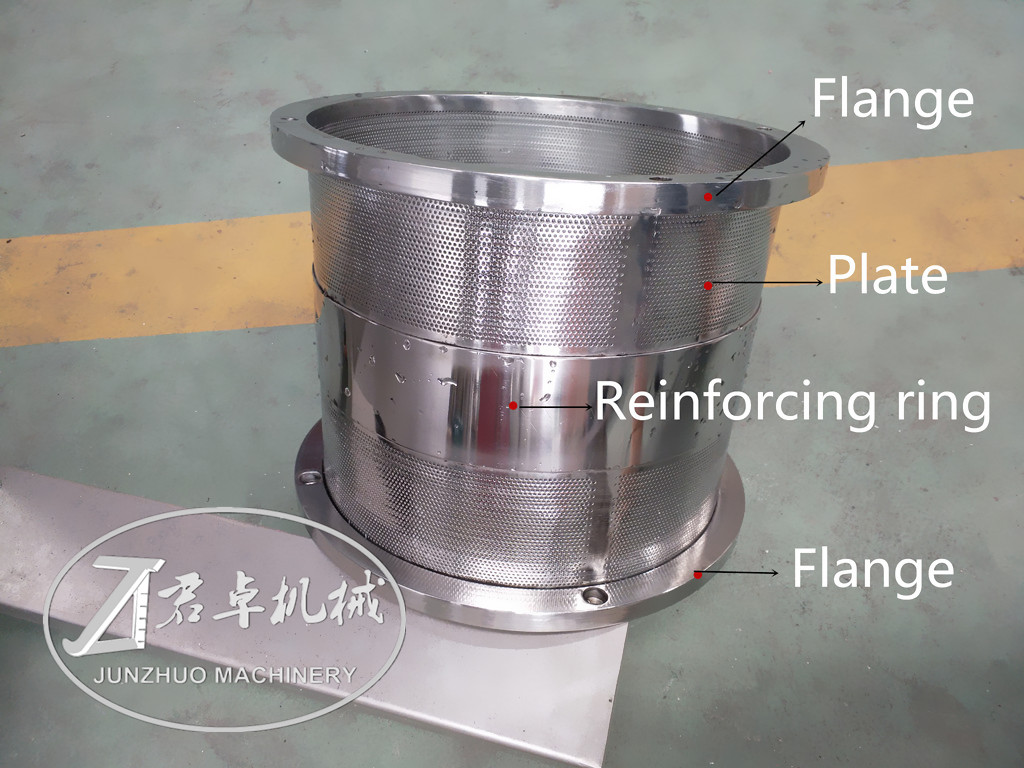

JUNZHUO MACHINERY offers all the spare parts, such as the blade,screen sieve,rotary knife and belts. The hole size of screen sizes is according to your requirement.

Granulating Part The blade and rotary knife move in opposite directions, so that the wet powder squeezes out of the screen hole.By extruding, the wet powder makes into granules. |

Screen Sieves The screen sieves are made by SS304, also it can be SS316L. The hole size is according to your requirement. A screen sieve is made by flange, plate and reinforcing ring. |

Control Panel It is very easy to operate. Screen touch panel is available. |

Discharge Normaly it is one discharge outlet, two discharge outlets are available. |

Our basket granulator can be used for making wet powder into granules, such as drinks powder, sauces and soups, detergent, pesticides and so on.

|  |  |

|  |  |

|  |  |

By continuing to use the site you agree to our privacy policy Terms and Conditions.