jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

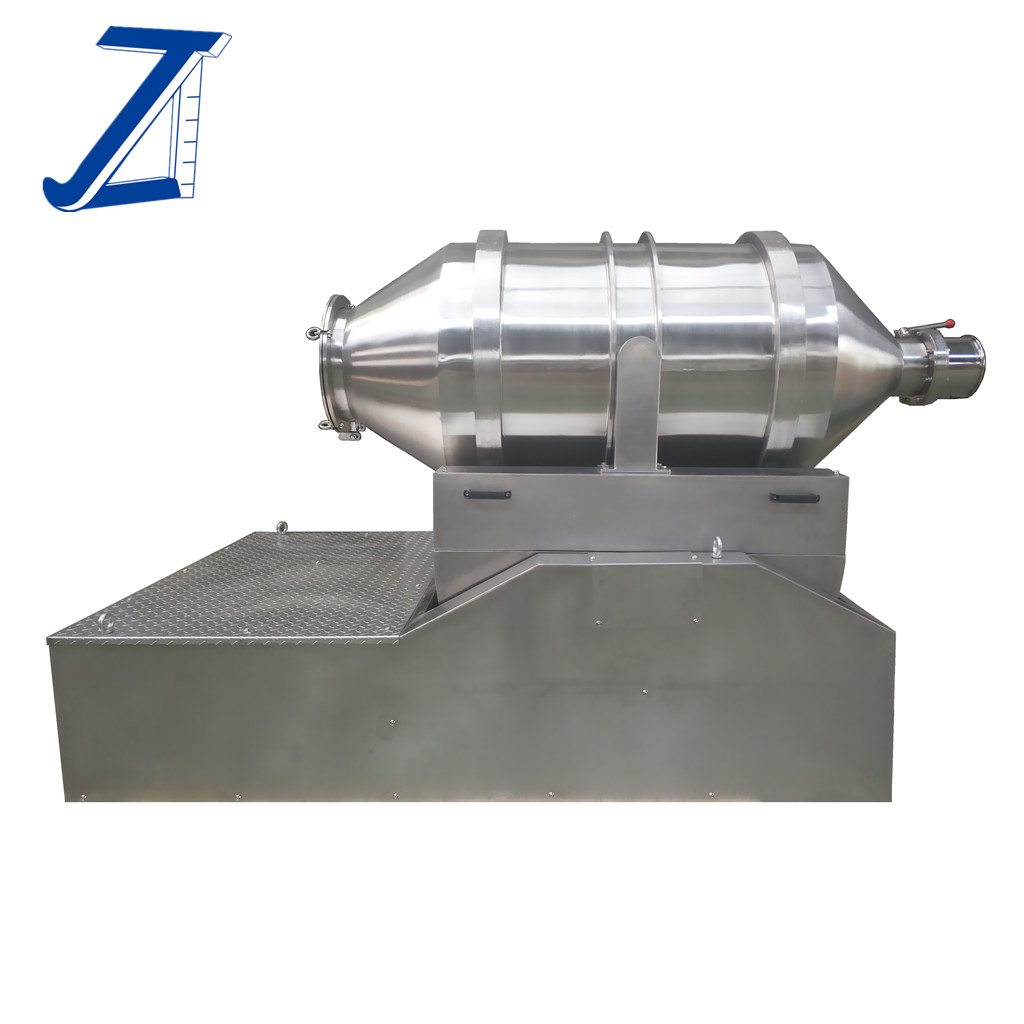

The 2D mixer is widely used in pharmaceutical, food, dye, feed, chemical fertilizer and pesticide industries and especially suitable for mixing various solid materials with large volume (1,000L~ 12,000L).

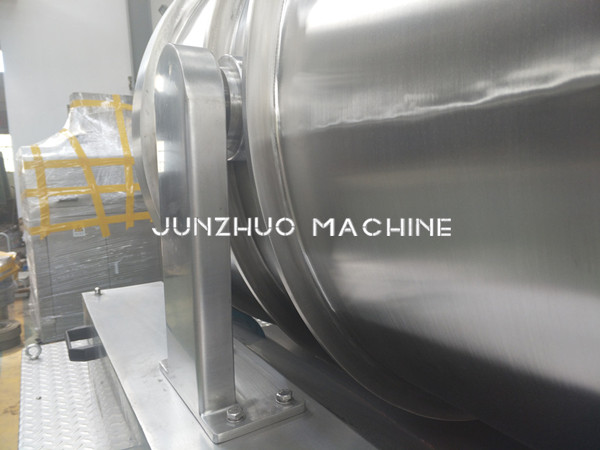

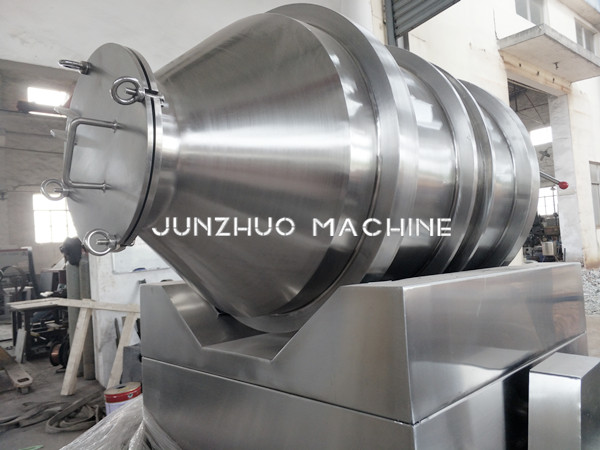

Two dimensional mixer

Main Application :

The 2D mixer is widely used in pharmaceutical, food, dye, feed, chemical fertilizer and pesticide industries and especially suitable for mixing various solid materials with large volume (300L~ 20,000L).

The mixing barrel swings while rotates so that the materials in the barrel can be fully mixed. Because the discharge port of the barrel is out of the barrel centerline, the mixer features quick mixing and discharging, as well as high volume mixing capacity.

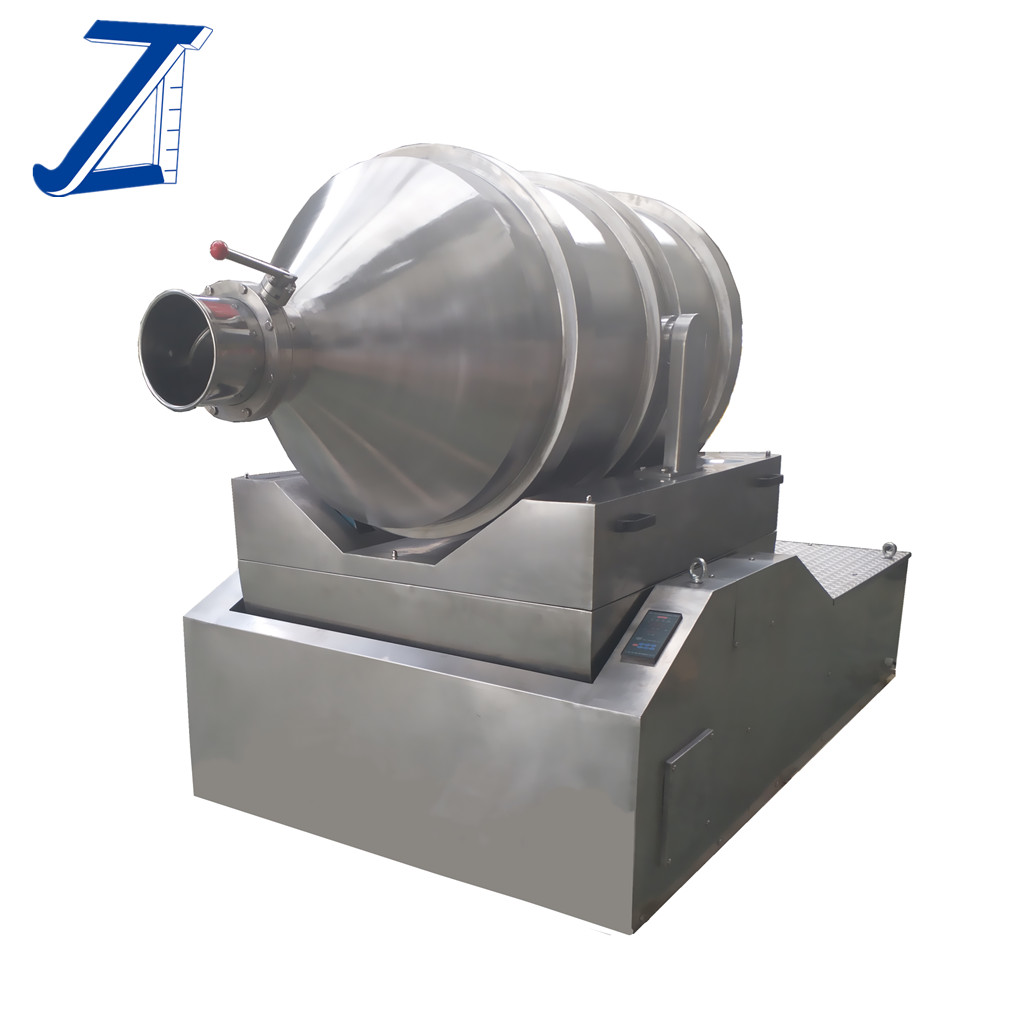

Working Principle:

2D mixer mainly consists of three big parts. Mainly, rotating cylinder, swinging rack and frame. The rotating cylinder lies on the swinging rack, supported by four wheels and its axial fixation is done by two stop wheels two of four wheels are driven by rotating power system to make the cylinder rotate. The swinging rack is driven by a set of crankshaft swinging bar which is mounted on the frame and the swinging rack is supported on the frame.

The rotating cylinder of EYH Two Dimensional Mixer can make two motions at the same time. One is the rotation of the cylinder and the other is swinging of the cylinder along the swinging rack. Materials to be mixed will be rotated when the cylinder is rotating, and will be mixed from left to right and vice versa when the cylinder is swinging. As a result of these two motions, mixer is suitable for mixing of all powder and granule materials.

Features

◇ Rotation & Swing motion makes materials mixed homogeneously

◇ Easy to feed and discharge

◇ Easy to operate, maintain and clean

◇ Low energy consumption

◇ Comply with GMP Standard.

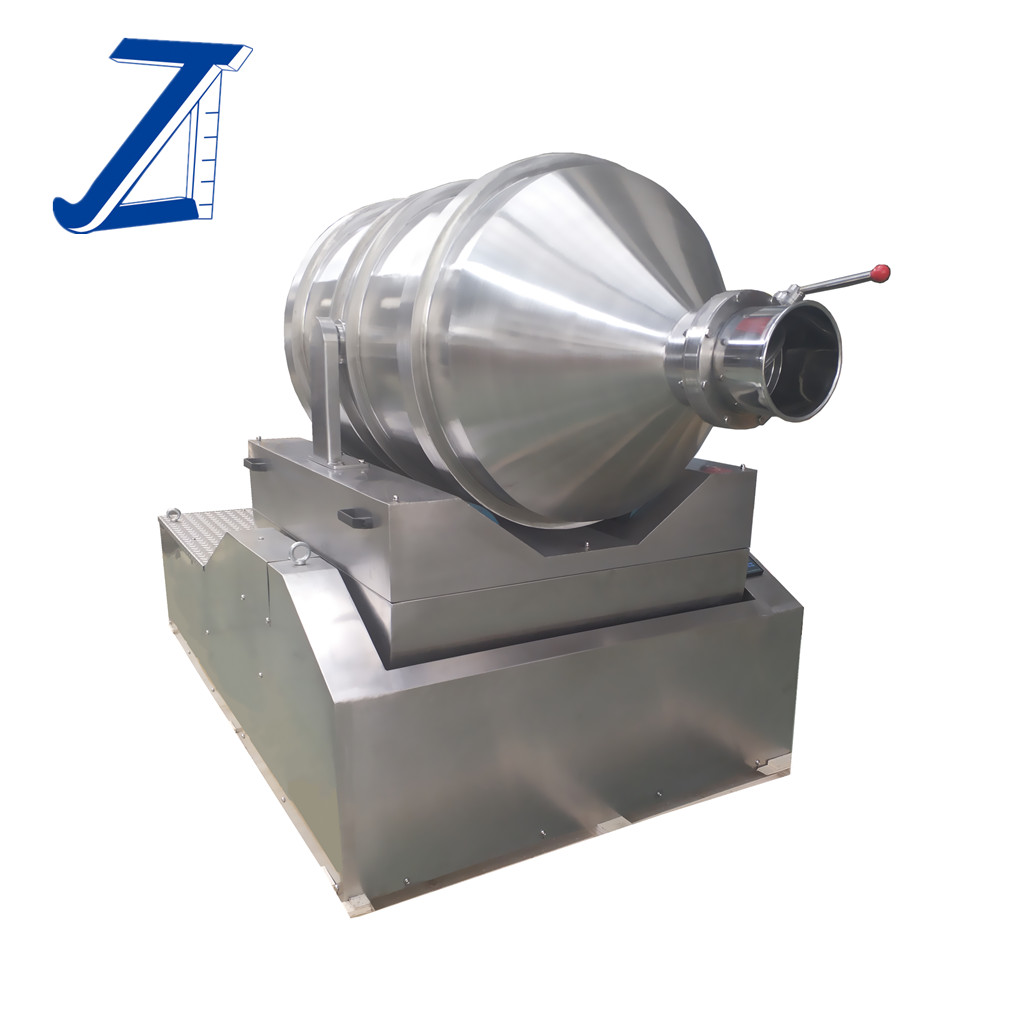

Features

1. Control system has more choices, such as push button, HMI+PLC and so on

2.The feeding system for this mixer can be by manual or pneumatic conveyor or vacuum feeder or screw feeder and so on.

3.The whole machine features novel design, compact structure, and good appearance, the evenness of mixing reaches 99% , and the volume charge factor is 0.6.

4. Smooth running, reliable performance, easy operation.

5. Highly polished inner and outer surfaces of the barrel, no dead comer, easy to discharge materials, easy to clear, no cross contamination. Confining to the requirement of GMP.

6. Machine materials: AISISUS304, AISISUS316L, and other material.

7. For the cleaning, we can supply the high pressure spray water device to clean the mixing inside.

8. Big volume(we can design and manufacture the 20000L machine and load 6000kg per batch)

| Model | Barrel Volume | Max. Loading Volume | Max. Loading Weight | Motor Power | Overall Size | Approx. Weight |

| EYH-300 | 300L | 180L | 90kg | 1.3kw | 1670X850X1050 mm | 340kg |

| EYH-600 | 600L | 360L | 180kg | 2.2kw | 1750X1140X1400 mm | 750kg |

| EYH-800 | 800L | 480L | 240kg | 3kw | 2700x1500x1750 mm | 1000kg |

| EYH-1000 | 1000L | 600L | 300kg | 3kw | 3250X1500X1750 mm | 1300kg |

| EYH-1500 | 1500L | 900L | 450kg | 4.4kw | 3300X1510X2100 mm | 1750kg |

| EYH-2000 | 2000L | 1200L | 600kg | 5.2kw | 3430X1810X2150 mm | 2600kg |

| EYH-3000 | 3000L | 1800L | 900kg | 7.0kw | 3640X1900X2490 mm | 3500kg |

| EYH-4000 | 4000L | 2400L | 1200kg | 9.5kw | 4200X2100X2550 mm | 4100kg |

| EYH-6000 | 6000L | 3600L | 1800kg | 13kw | 5100X2350X3250 mm | 6100kg |

| EYH-8000 | 8000L | 4800L | 2400kg | 13kw | 5800X2600X3385 mm | 7900kg |

| EYH-10000 | 10000L | 6000L | 3000kg | 18.5kw | 6350X2800X3850 mm | 10000kg |

| EYH-12000 | 12000L | 7200L | 3600kg | 18.5kw | 6500X3000X4250 mm | 13000kg |

| EYH-15000 | 15000L | 9000L | 4500kg | 22kw | 7200X3200X 4500 mm | 15000kg |

EYH-20000 | 20000L | 12000L | 6000kg | 30kw | 7800X3400X4570 mm | 18000kg |

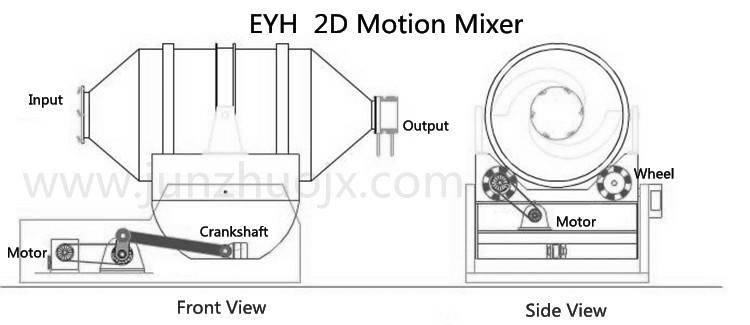

Output |  Input |

Rotation Direction |  Swinging Rack |

Driven Motor |  Drum |

Covered by film |  Package |

By continuing to use the site you agree to our privacy policy Terms and Conditions.