jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

Horizontal Ribbon Mixer For Different Powder is a pioneer product researched and a new high-efficiency mixer. It is widely used in the solid-solid (powder material) and solid-liquid (powder material & fluidity material) mixing in the field of chemical industry, pharmacy, foodstuff industry, etc.

Ribbon Mixer

Main Application :

Horizontal Ribbon Mixer For Different Powder is a pioneer product researched and a new high-efficiency mixer. It is widely used in the solid-solid (powder material) and solid-liquid (powder material & fluidity material) mixing in the field of chemical industry, pharmacy, foodstuff industry, etc.

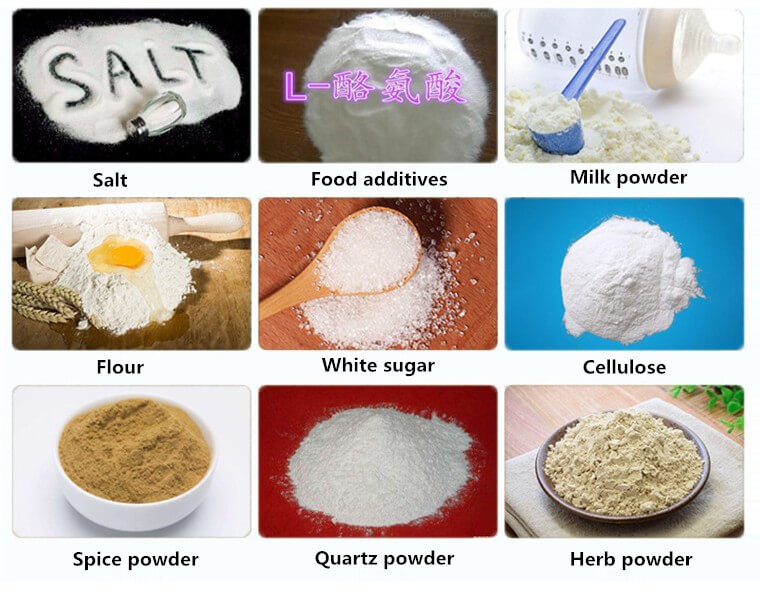

*Solid+Solid(powder or granules)

*Solid+Liquid(20%-30%)

Working Principle:

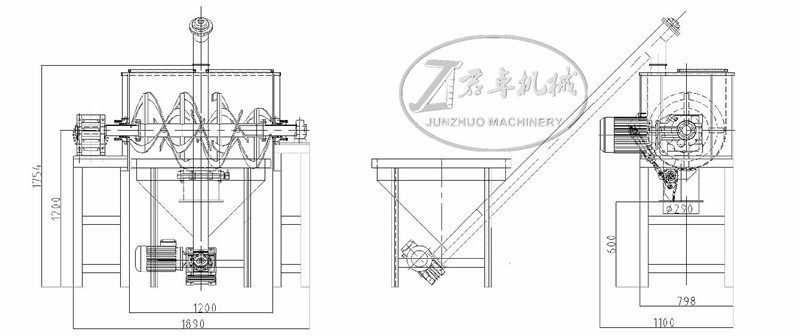

Ribbon Mixer is mainly comprised of mixing barrel, spiral ribbon and driven parts. The spiral ribbon is made of two layers. That is, the inner ribbon makes the materials move outwards, while the external ribbon makes the material move inwards which forms a good circulation of material. Ribbon moves so circumferentially that the mixer could achieve fine mixing efficiency in a very short time.

Features

1) Simple structure in horizontal U shape, easy in installation and maintenance.

2) Adopting advanced world famous brand components in pneumatic parts, motor, electric parts, bearings and operation parts.

3) Hermetic seals are adopted on both sides of our ribbon mixer,

4) There is safety net on the cover, so that operator cannot reach out arms into the mixer, danger can be prevented.

5) Pneumatic valve is adopted to discharge material

| Model | Operation Volume | Rotation Speed | Motor Power | Overall Size | Approx. Weight |

| WLDH-0.1 | 60L | 76rpm | 2.2kw | 1080(L)×758(W)×615(H) mm | 330kg |

| WLDH-0.3 | 180L | 66rpm | 4kw | 1550(L)×812(W)×1015(H) mm | 780kg |

| WLDH-0.5 | 300L | 66rpm | 5.5kw | 1975(L)×1059(W)×1120(H) mm | 955kg |

| WLDH-1 | 600L | 41rpm | 11kw | 2340(L)×1380(W)×1455(H) mm | 1400kg |

| WLDH-2 | 1200L | 33rpm | 18.5kw | 2480(L)×1651(W)×1805(H) mm | 2500kg |

| WLDH-3 | 1800L | 33rpm | 22kw | 2945(L)×1896(W)×1980(H) mm | 3300kg |

| WLDH-4 | 2400L | 29rpm | 22kw | 3038(L)×1946(W)×2205(H) mm | 3600kg |

| WLDH-5 | 3000L | 29rpm | 30kw | 3932(L)×2010(W)×2035(H) mm | 4620kg |

| WLDH-6 | 3600L | 26rpm | 37kw | 3938(L)×1882(W)×2246(H) mm | 5300kg |

| WLDH-8 | 4800L | 26rpm | 45kw | 3986(L)×2160(W)×2516(H) mm | 6800kg |

WLDH-10 | 6000L | 19rpm | 55kw | 4500(L)×2270(W)×2667(H) mm | 8900kg |

Flexible material, polishing and color choice Normally, the machine material are all SUS 304. If you have high standard of raw material, we will make SUS 316L The surface treatment includes mirror polishing, sandblasting and wiredrawing. Also, we provide paint color service over the mixer. |

Various discharging method Manual, pneumatic, and electric discharging method for your choice. |

Customized safety grid Safety grid is used to avoid personal injury, we support if you have the requirement for screen size and structure. |

Motor, electrical products brand Motor: Siemens, ABB, DaZhong etc Frequency changer: Siemens, ABB etc Contactor: Schneider, Delixi, Chint etc Bearing: SKF |

By continuing to use the site you agree to our privacy policy Terms and Conditions.