jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

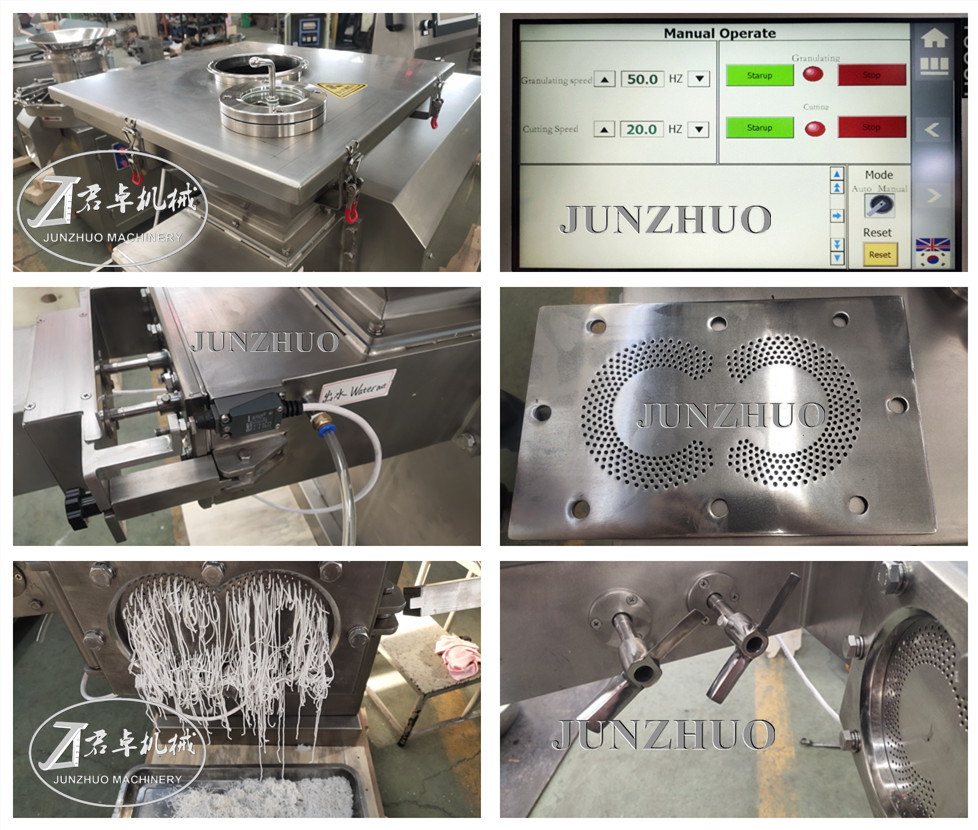

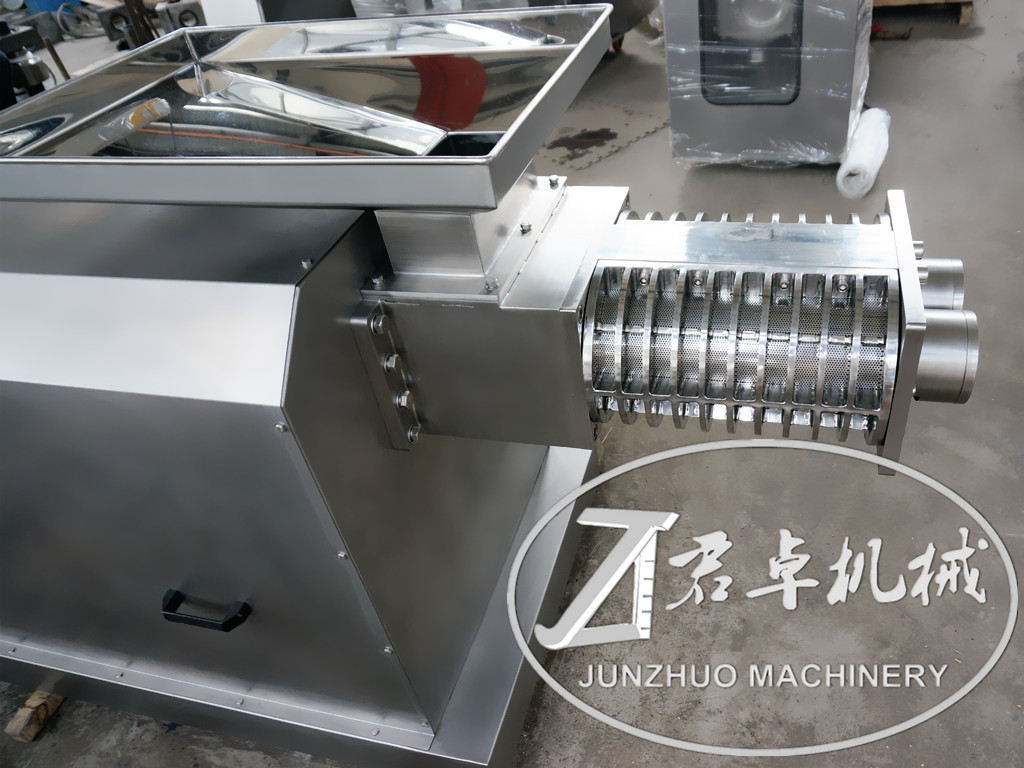

This extruder is controlled by PLC, it is easy to use. It is equipped with cutting knives so that the granule length is adjustable.

DOUBLE SCREW EXTRUDER

The popularity of twin screw extruders is attributed to its versatility and applicability to a remarkably wide range of materials. Besides this, extruders allow continuous processing and are capable of delivering high value, high quality products in large quantities. The growing number of industrial applications of extrusion technology in the last few decades has led to an increasing interest in understanding the extrusion process. However, the complexity of the extrusion process such as the shear, mixing, flow performance and the material interaction make the study very challenging and empirical approaches have made little contribution to the fundamental understanding of the process.

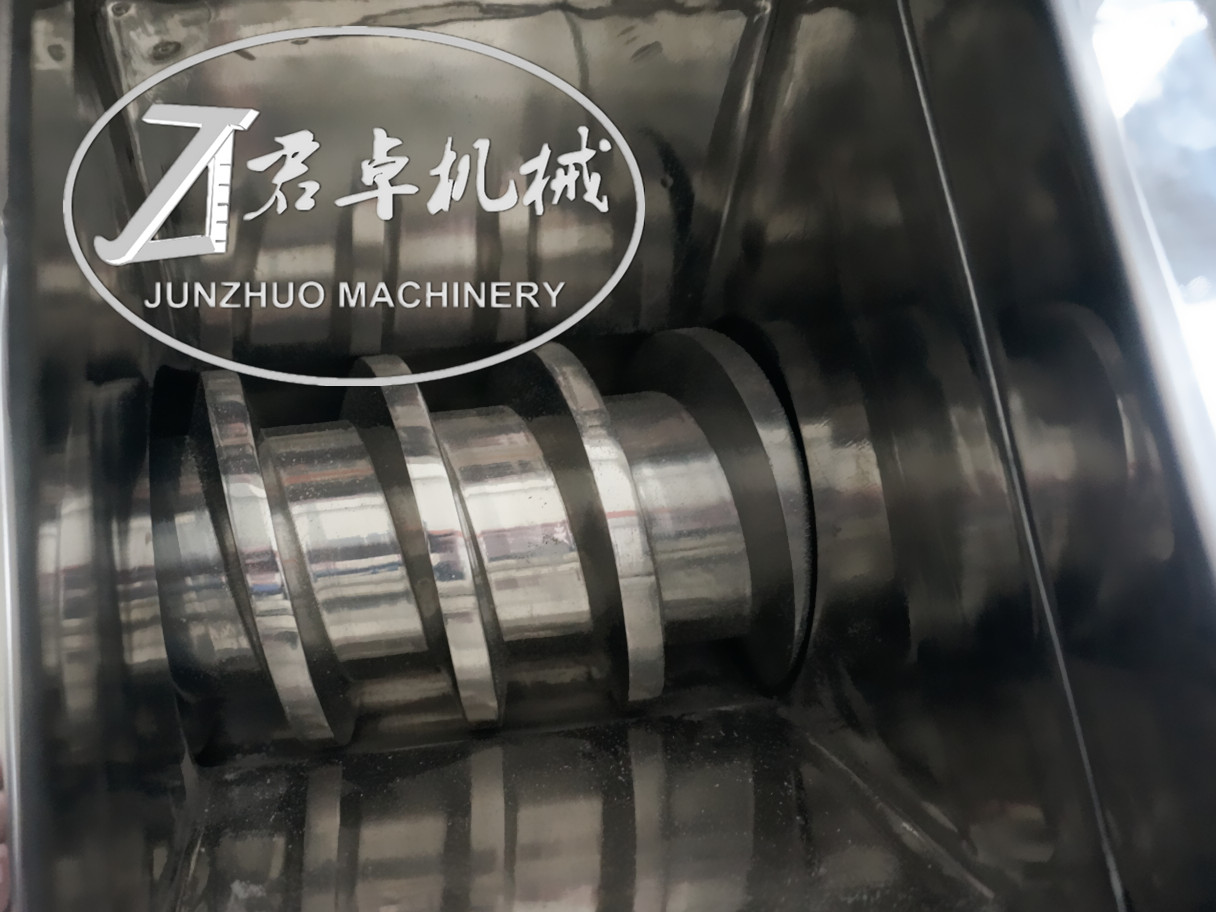

JUNZHUO MACHINERY single/double screw extruder is suitable for most low pressure wet extrusion processes used in solid dosage processing. Extrusion performed by two detachable, contra rotating gears. This action generates minimum heat and does not work the product excessively. This makes it ideally suited for extruding pharmaceutical products. Feeding can be done manually or automatically by auger feed.

Technical data

Screw Diameter:120mm*2

Screen Sieve Size:1--8mm

Motor Power: 7.5kw

Cutter Power:0.2kw

Rotation Speed:70r/min

Capacity:30-450kg/h

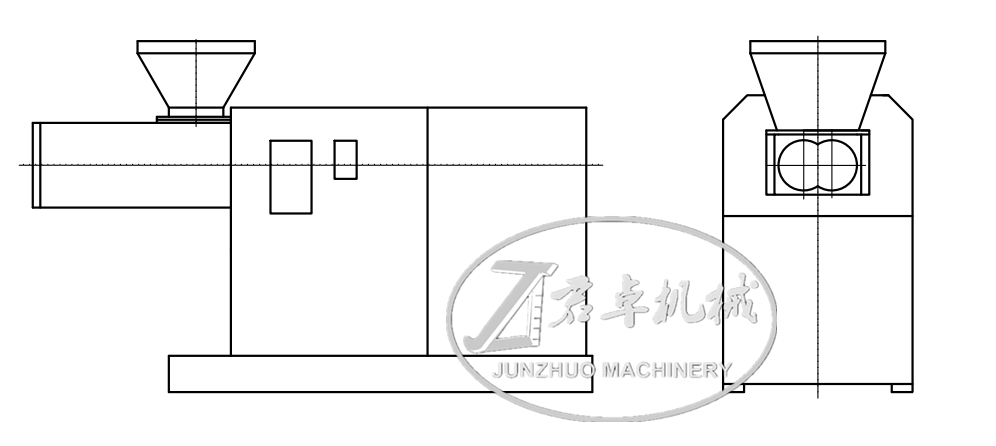

Overall Size:1800*600*1400mm

Approx. Weight:800kg

Working Principle

The motor power is driven from the v-belt wheel to the gear box, power is distributed through the drive parts inside the gear box, and the double screws start working. Add raw material into feeding hopper, the wet mixed powder is extruded by the left and right screws and forced through screen mesh to be columnar particles.The granule length can be adjusted by cutter.

Salient Features :

Designed as per cGMP – Current Good Manufacturing Practices

Contact parts in AISI 316, AISI 304 or MS as desired by customer.

Different models in extruders such as Single Screw extruder, Double Screw Extruder,Axial extruder, Radial extruder.

Length of extrusions is adjustable.

Up to 90% uniformity (substantially formulation dependent).

Change of extrusion diameter/ Pellet size by changing screen sieve.

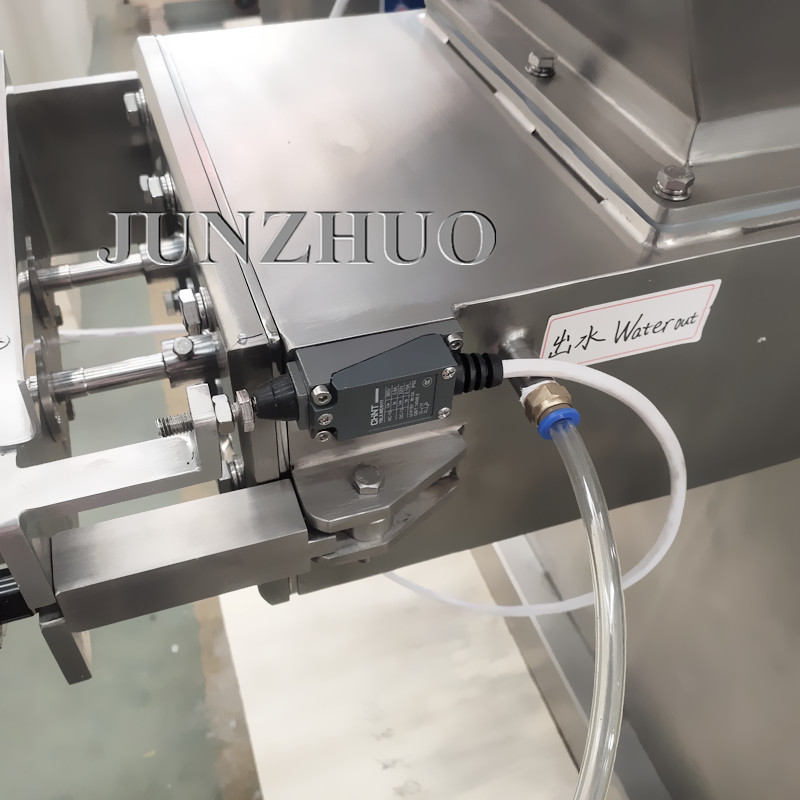

Continuous cooling arrangement during extrusion operation for pressing roller.

| Model | JZL-50 | JZL-80 | JZL-100 | JZL-120 | JZL-140 | JZL-180 | JZL-200(customized design) | JZL-200 |

| Capacity | 10-80kg/h | 30-180 kg/h | 30-300 kg/h | 30-450 kg/h | 150-500 kg/h | 500-1200 kg/h | 200-2500 kg/h | 200-2500 kg/h |

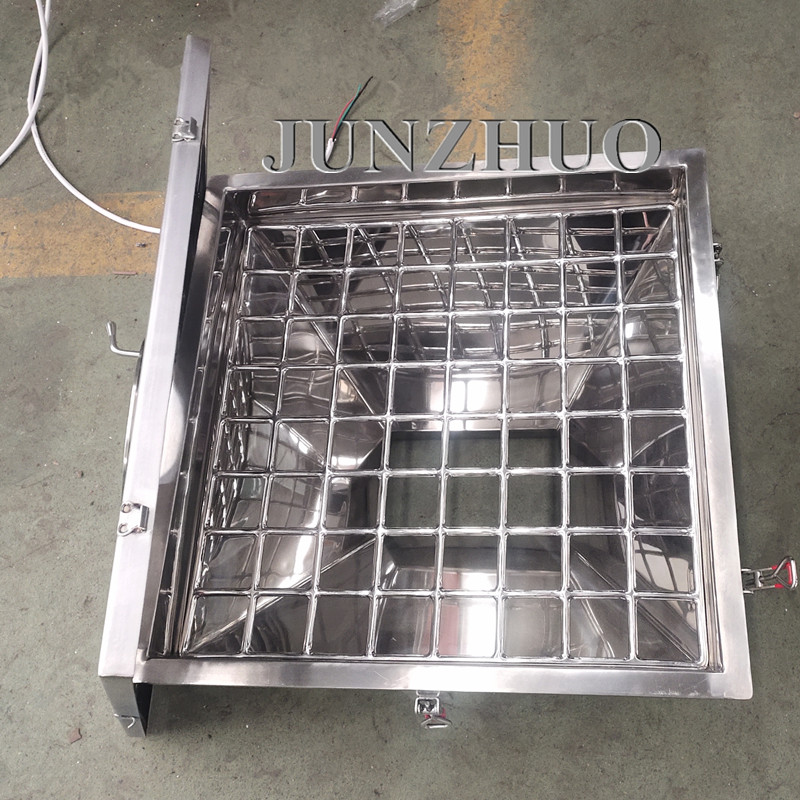

| Screen Sieve | φ1-8mm | φ1-8mm | φ1-8mm | φ1-8mm | φ2-8mm | φ2-20mm | φ2-20mm | φ2-20mm |

| Screw Diameter | φ50*2 | φ78*2 | φ100*2 | φ120*2 | φ138*2 | φ180*2 | φ200*2 | φ200*2 |

| Motor Power | 2.2kw | 4kw | 5.5kw | 7.5kw | 11-15kw | 22-30kw | 30kw | 40kw |

| Rotation Speed | 80r/min | 80r/min | 80r/min | 70r/min | 60r/min | 60r/min | 60r/min | 60r/min |

| Overall Size | 820*440*720mm | 1200*600*1000mm | 1400*650*1200mm | 1500*650*1250mm | 2000*750*1150mm | 2440*1450*1200mm | 2450*1650*1200mm | 2680*1650*1200mm |

| Approx. Weight | 170kg | 450kg | 650kg | 780kg | 1100kg | 2000kg | 1750kg | 3000kg |

Twin screw extruders consist of two intermeshing, co-rotating screws mounted on splined shafts in a closed barrel. Due to a wide range of screw and barrel designs, various screw profiles and process functions can be set up according to process requirements. The major advantage of intermeshing co-rotating twin screw extruders is their remarkable mixing capability which confers exceptional characteristics to extruded products and adds significant value to processing units.

In twin screw extrusion processing, the raw materials may be solids (powders, granulates, flours). Extruded products are chemically modified polymers, textured food and feed products, cellulose pulps, etc.

Screen Sieve, which is made by SS304 or SS316L, granule size from 0.8mm to 5mm

|  |

Single/Double Screw, twin screw extruder offers higher process productivity as compared to single screw extruder.

Single Screw |  Double Screw |

Radial /Axial output, the granules of radial extruder is side discharged, and anxial extruder is front discharged.

Axial extruder |  Radial extruder |

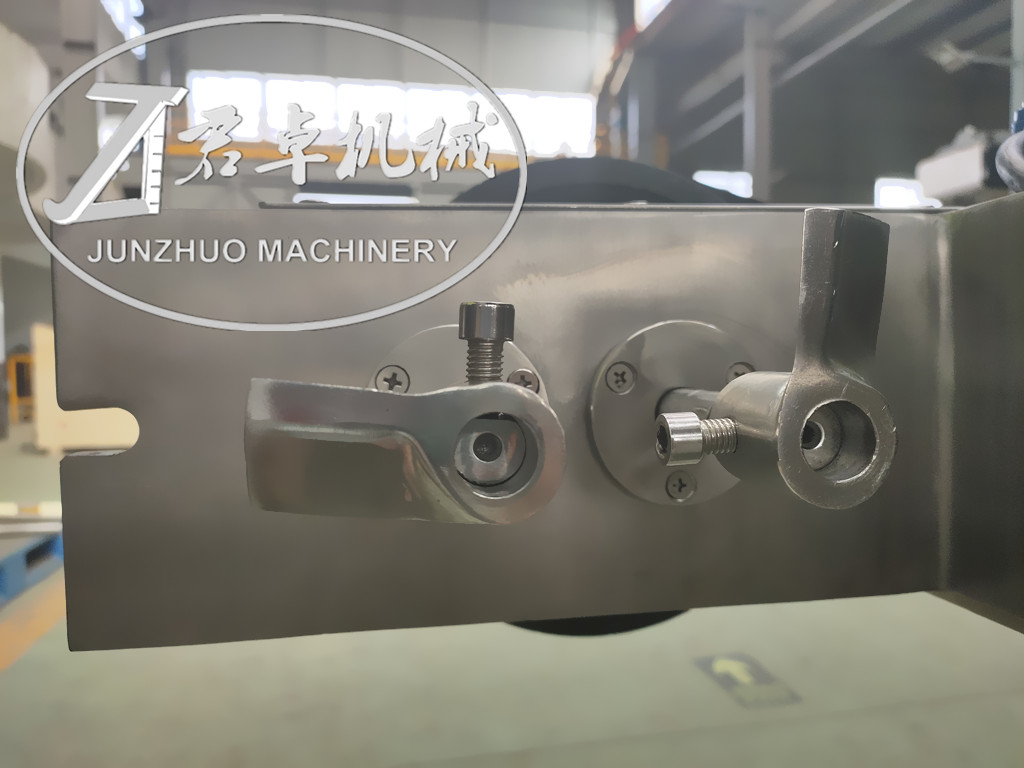

Cutting Knife, which can adjust the granule length.Only axial extruder can be equipped with it.

Cutting knife |  Cutting knife |

By continuing to use the site you agree to our privacy policy Terms and Conditions.