jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

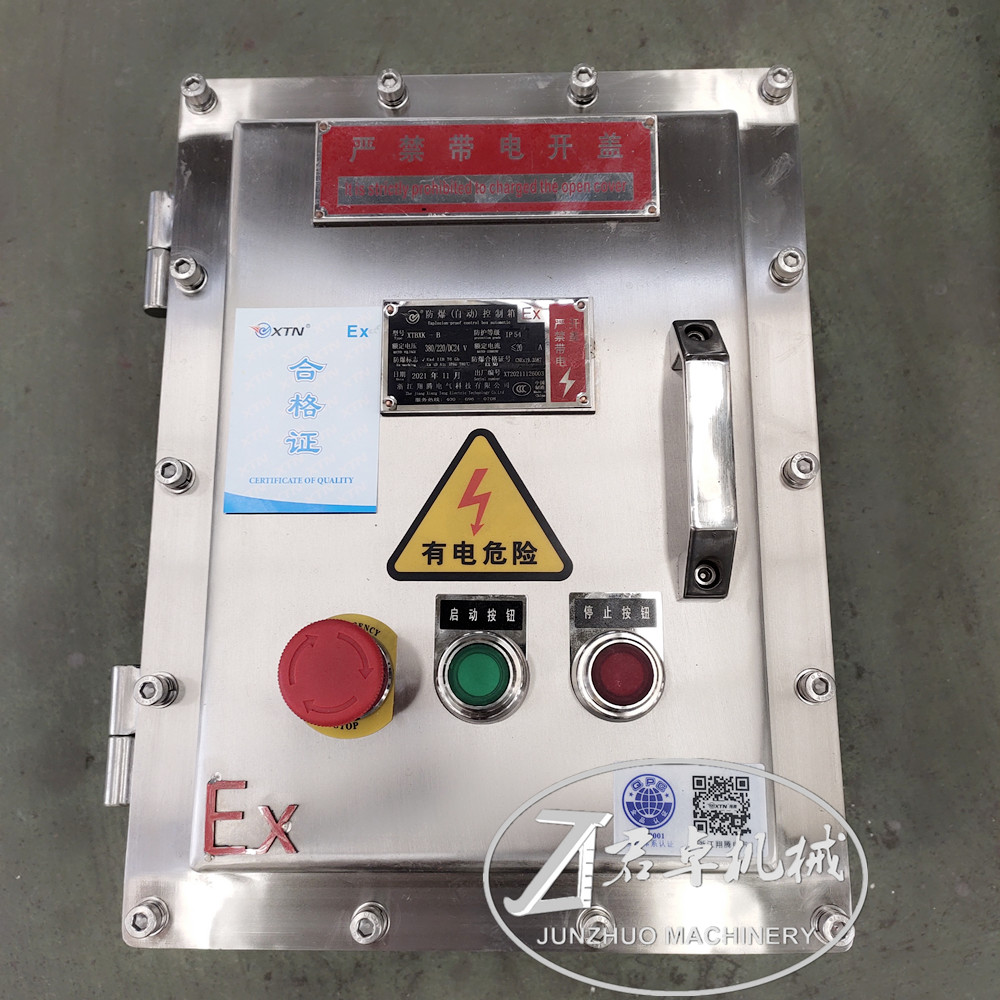

This oscillating granulator is customized design, it adopts explosion-proof motor, cooling system and hermetic seal. We can provide all the spare parts and make the machine as your requirement.

JUNZHUO MACHINERY YK160 series oscillating granulators are widely used in pharmaceutical, food, chemical, cosmetic and nutrition industries.

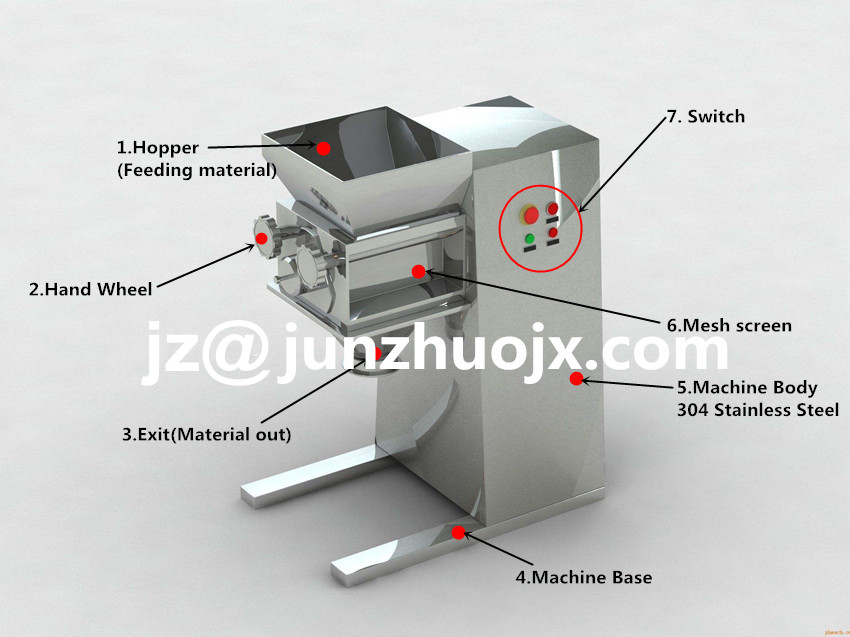

The oscillating granulator made by JUNZHUO MACHINERY is known for its robust and durable structure, all contact parts of the machine including front portion is made out of SS 304 or SS316L, which can be mirror polished or dull finish. Working capacity is max. 400 kg / h depending on the material and mesh width of the sieve used. Usually it ranges from 1-5mm, other special sieves are available on request. An emergency stop helps to prevent injuries.

It is quite easy to operate and clean which ensures long life as well as great economy when it comes to the cost of screen. The oscillating granulator is fitted with castor wheel which helps in smart mobility. The machine is also highly flexible when it comes to different kinds of projects and can be used for high yield functions. These factors make this machine extremely user friendly.

Customized Design Option

Explosion-proof design

PLC control

316L for contact part or total machine

Quick opening arrangement

Discharge distance from ground

Discharge hole design

Dust collector

Inverter

Water chilling unit

JUNZHUO MACHIERY offers all spare parts to you, if there is any question please contact with jz@junzhuojx.com !

Model size from YK60 to YK350, YK-60 oscillating granulator is the smallest model, which can be used for lab testing.

| Model | Capacity | Rotor Size | Power | Rotor Speed | Overall size | Weight |

| YK-60 | 1-15kg/h | 60 mm | 0.55kw | 65r/min | 430*190*475mm | 30 kg |

YK-60 New (new) | 1-15kg/h | 60 mm | 0.55kw | 65r/min | 520*300*875mm | 60kg |

| YK-80 | 15-50 kg/h | 80 mm | 0.75 kw | 55 r/min | 950*300*610mm | 80 kg |

| YK-100 | 30-200 kg/h | 120 mm | 1.1 kw | 55 r/min | 700*400*1050mm | 150 kg |

| YK-140 | 80-300kg/h | 140 mm | 2.2kw | 55r/min | 900*620*1050mm | 180 kg |

| YK-160 | 50-300 kg/h | 160 mm | 3 kw | 60r/min | 850*820*1080mm | 210 kg |

| YK-160D | 100-400 kg/h | 160 mm | 5.5 kw | 55r/min | 950*780*1210mm | 300 kg |

| YK-160Z | 100-400 kg/h | 160 mm | 5.5 kw | 40 r/min | 1160*720*1250mm | 450 kg |

| YK-250 | 150-550 kg/h | 250 mm | 5.5 kw | 40-50 r/min | 1150*820*1270mm | 600 kg |

| YK-250D | 200-600 kg/h | 250 mm | 7.5 kw | 40-50 r/min | 1250*950*1300mm | 750 kg |

| YK-250Z | 300-600 kg/h | 250 mm | 11 kw | 40 r/min | 1700*900*1350mm | 1000kg |

| YK-320 | 300-800 kg/h | 320 mm | 7.5 kw | 35 r/min | 1400*800*1500mm | 800 kg |

| YK-320D | 300-800 kg/h | 320 mm | 11 kw | 35 r/min | 1450*800*1500mm | 1050 kg |

| YK-320Z | 300-800 kg/h | 320 mm | 15 kw | 35 r/min | 1700*900*1400mm | 1250 kg |

| YK-350 | 400-1200 kg/h | 350 mm | 11-15 kw | 35 r/min | 2100*860*1540mm | 1250 kg |

Oscillating Granulator has one rotor horizontal axis at about 360 degree. There is one half round sieve mounted at the bottom of the rotor. Product is charged from the top through in feeding hopper and material falls on the rotor. The particles are broken by a set of oscillating bars arranged in cylindrical form over a screen of suitable mesh. Due to the sharp edges on rotor, the downsizing of particle takes place and through sieve material gets pushed outward from the bottom opening. The granules can be produced in varying sizes depending on the employed sieve mesh.

JUNZHUO MACHINERY offerrs all the spare parts, such as the rotor,screen sieve and hand wells. Screen sieves can be made by perforated plate or mesh sieve or nylon, it just depends on your requirement.

Screen Sieves

Nylon Sieve |  Wire Mesh |  Perforated Plate |

Others

Hand Wheels |  Single Rotor |

By continuing to use the site you agree to our privacy policy Terms and Conditions.