jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

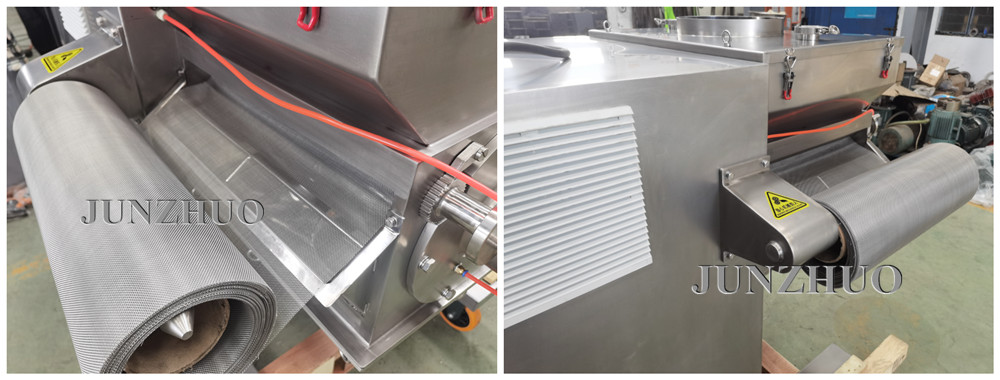

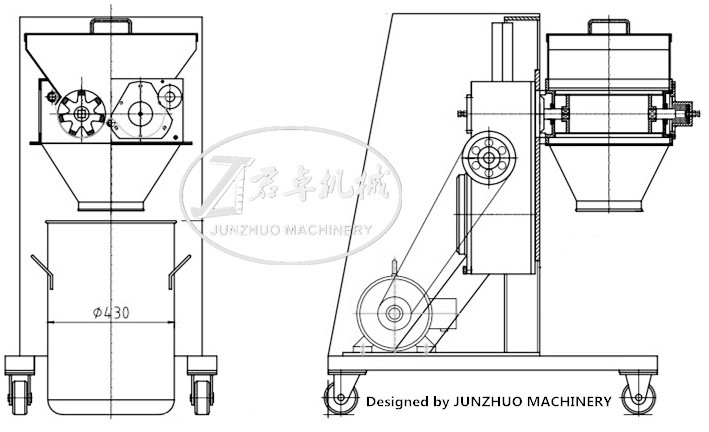

This is YK250S double rotor oscillating granulator is unique design, which is able to change the screen sieve continously. In this way, it will save a lot of time to change the screen sieve. It is a hermetic seal type oscillating granulator, this will prevent material from entering both ends.

The YK Series Double Rotor Granulator covers a full range of capacities from 200kg an hour up to 4500kg an hour, each of the granulating machines provides a convenient and cost effective way of turning powders into granules in the pharmaceutical, food, chemical ceramics or related industries. Suitable for wet and dry granulation, these oscillating granulators also can be used for breaking down agglomerates into granules.

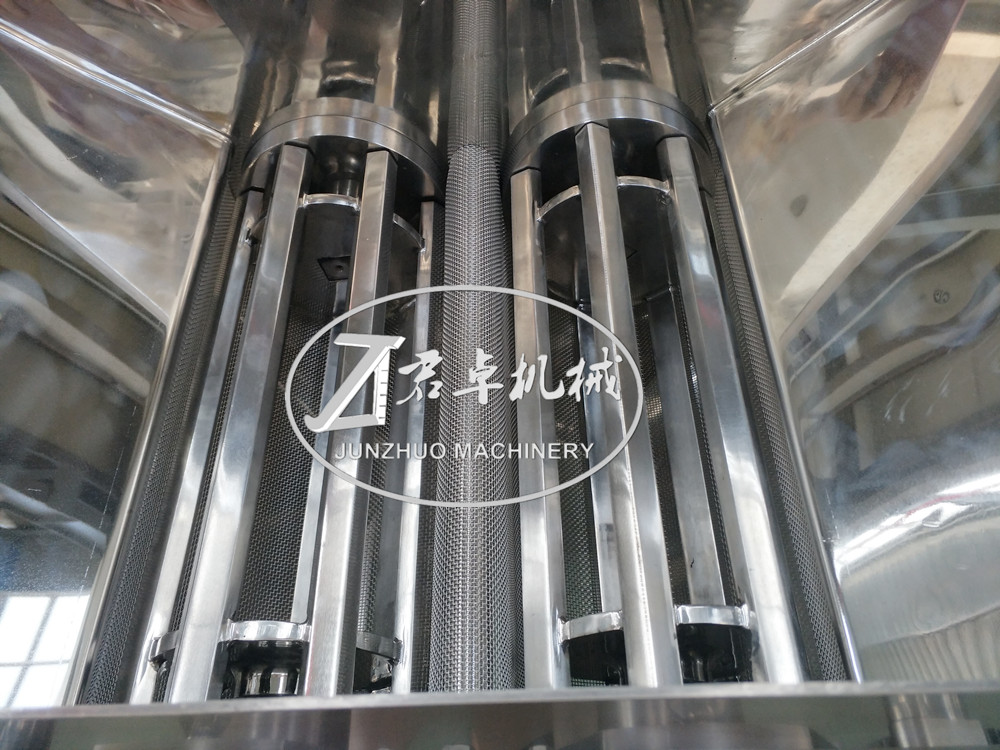

The YK Double Rotor Series consists of the YK160S, YK250S, YK320S, YK350S and YK400S, with the number denoting the diameter of the machine’s roller. They each work on the same principle, involving an oscillating metal cylinder that acts against an easily changed metal mesh. With powerful motors, adjustable speed, and carefully engineered oscillation for maximum efficiency and minimum energy requirement, these machines produce granular materials of the highest quality and consistency. Small amounts of active ingredients and the liquid binder that locks the powder as granules to prevent segregation.

All granulators in the series are built from stainless steel, and constructed to meet GMP standards. They are simple to operate and maintain, easy to clean, and designed to satisfy the stringent hygiene requirements needed for food production. They are also rugged and durable, with minimal maintenance needs, and will provide reliable operation for many years into the future.

Working smoother with the design of two groups of rotors, which can improve capacity effectively. We also can provide ODM&OEM production.

Model size from YK160S to YK400S, we can supply customized design for different requirements.

| Model | Capacity | Rotor Size | Power | Rotor Speed | Overall size | Weight |

| YK-160S | 200-550kg/h | 160mm*2 | 5.5kw | 45r/min | 1150*720*1130mm | 650 kg |

YK-160SD | 300-700 kg/h | 160mm*2 | 7.5kw | 40r/min | 1220*720*1220mm | 700kg |

| YK-160SZ | 300-700 kg/h | 160mm*2 | 11 kw | 35 r/min | 1350*800*1250mm | 780 kg |

| YK-250S | 350-1000 kg/h | 250mm*2 | 11 kw | 40 r/min | 1400*950*1520mm | 1100 kg |

| YK-250SZ | 400-1000 kg/h | 250mm*2 | 15 kw | 38r/min | 1550*950*1520mm | 1250 kg |

| YK-320S | 400-1200 kg/h | 320mm*2 | 11 kw | 35r/min | 1840*1060*1410mm | 1250 kg |

| YK-320SD | 400-1200 kg/h | 320mm*2 | 15 kw | 35 r/min | 1850*1060*1410mm | 1350 kg |

| YK-320SZ | 500-1200 kg/h | 320mm*2 | 18.5 kw | 35 r/min | 2000*1060*1450mm | 1500 kg |

| YK-350S | 500-1500kg/h | 350mm*2 | 18.5 kw | 35 r/min | 2150*1100*1540mm | 1800 kg |

| YK-400S | 1800-4500 kg/h | 400mm*2 | 22 kw | 28 r/min | 2500*1680*1900mm | 2600kg |

Double Rotor Oscillating Granulator has double rotor with seven edges, which oscillate on horizontal axis at about 360 degrees. There is one half round sieve mounted at the bottom of the rotor. Product is charged from the top through in feed hopper and material falls on the rotor lades. The particles are broken by a set of oscillating bars arranged in cylindrical form over a screen of suitable mesh. Due to the sharp edges on rotor, the downsizing of particle takes place and through sieve material gets pushed outward from the bottom opening.

JUNZHUO MACHINERY offerrs all the spare parts, such as the rotor,screen sieve and hand wells. Screen sieves can be made by perforated plate or mesh sieve or nylon, it just depends on your requirement.

Screen Sieves

Nylon Sieve |  Wire Mesh |  Perforated Plate |

Others

Hand Wheels |  Double Rotor |

Our oscillating granulator can be used for making wet powder into granules, also it can crush dry blocks into small pieces.

By continuing to use the site you agree to our privacy policy Terms and Conditions.