jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

The machine has a very good effect for different kinds of spices, like chilli, pepper, black pepper, white pepper, green pepper, cinnamon, cumin, bandits, nutmeg, cardamom, red yeast rice, red pepper, garlic, star anise, cloves, Amomum Tsaoko, geraniol, turmeric, ginger, fennel, anise, angelica and other material with high content of oil or fiber. For root, herb and leaf, the grinding effect is also good.

In the pharmaceutical and food processing industries, a hammer mill is a necessary machine. It can crush, pulverise, shred, grind, and reduce material to appropriate sizes. Swinging hammer heads are coupled to a rotor that revolves at a high speed inside a rigid casing in a hammer mill.

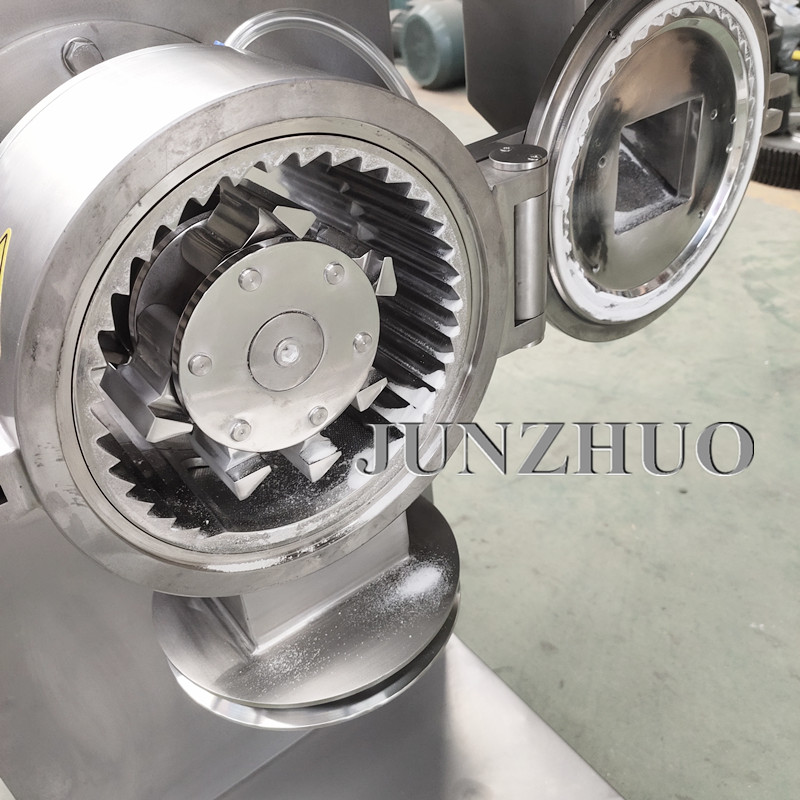

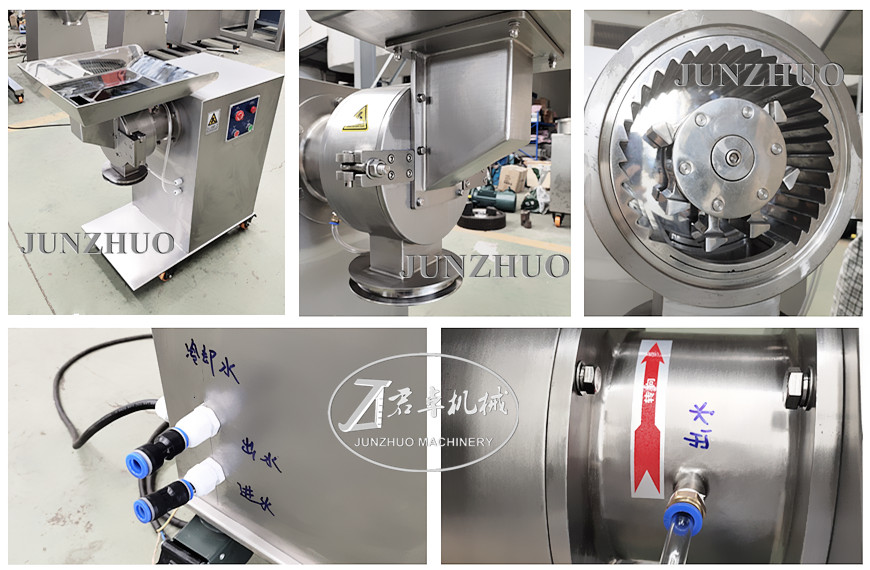

By adopting the design of front door, the device is convenient for disassembly, installation, cleaning, replacement of the sharpening rotor. Screen size of different specifications (0.4 ~3mm) fully meets the requirements of crushing particle size, and can be customized according to the actual situation of clients.

Working Principle

The material was repeatedly struck by ganged hammers or chopping knives. These components spin at a high rate, reducing materials to the size required. Only particles of the same dimension as the sieve size pass through sieves. Otherwise, the hammers will continue to pound these materials until they reach the desired size. Essentially, the material is attacked by a repetitive mix of knives/hammer impact and contact with the milling chamber’s wall within this chamber. Furthermore, particle collisions play an important role in the size reduction process. It is not recommended that the crushing chamber be opened while the machine is running.

Technical Data

型号Model | ZF-200型 |

生产能力Capacity(kg/h) | 10-60 |

粉碎电机功率Crushing power(kw) | 3 |

转速Speed | 5500rpm转/分 |

外形尺寸Overall Size(mm) | 930*500*930 |

重量Approx. Weight(kg) | 150 |

By continuing to use the site you agree to our privacy policy Terms and Conditions.